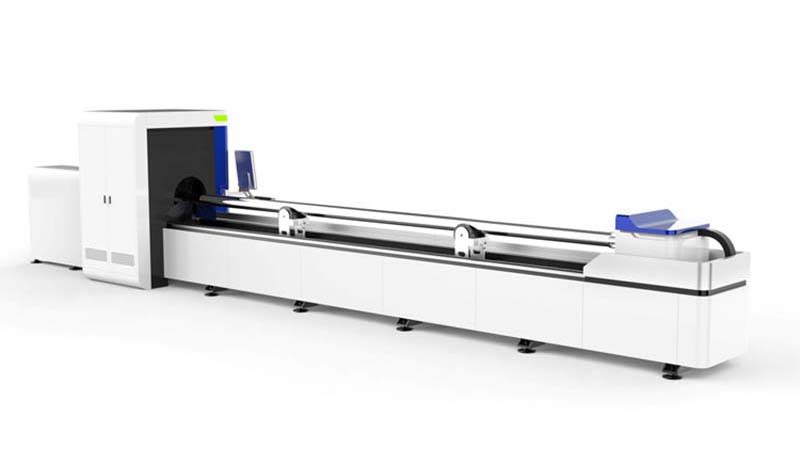

Ka nts'etsopele e potlakileng ea theknoloji ea laser,mechine ea ho itšeha ka laser pipeli sebelisoa haholo liindastering tse ngata.Ho hlaha ha lisebelisoa tsa ho seha lipeipi tsa laser ho tlisitse liphetoho tse khelosang mokhoa oa ho itšeha oa indasteri ea lipeipi tsa tšepe tsa setso.Mochini oa ho itšeha oa phala ea laser o na le litšobotsi tsa boiketsetso bo phahameng, ts'ebetso e phahameng, le tlhahiso e phahameng.Bakeng sa liphaephe tsa lisebelisoa tse fapaneng, ha ho hlokahale hore u nke sebaka sa li-saha tse lumellanang, 'me ha ho hlokahale ho emisa bohareng.E loketse haholo bakeng sa tlhahiso ea bongata.

E le ho boloka ts'ebetso e phahameng ea mochine oa ho itšeha oa phala ea laser, ho hlokahala ho boloka thepa kamehla, kahoo ho boloka mochine oa ho itšeha phala joang?Ntle le tlhokomelo ea bethe ea lisebelisoa, tlhokomelo ea chuck e boetse e bohlokoa haholo.Lintlha tse latelang ke tse 4 tsa ho boloka chuck.

1. Bakeng sa lubrication ea chuck, sebelisa lubricant ho chuck kamehla ho etsa bonnete ba hore chuck e ntse e ka ba le ho nepahala ho phahameng nakong ea ho sisinyeha.Ela hloko ha u tlotsa.Ho tlotsa ka nepo ho ka etsa hore chuck ea pneumatic e hlolehe ho sebetsa ka mokhoa o tloaelehileng ha khatello ea moea e le tlase, matla a ho koala a fokotsehile, ho nepahala ha clamping ho fokola, moaparo ha oa tloaeleha kapa o tsitsitse, kahoo ela hloko ts'ebetso e nepahetseng ea lubrication ha u tlotsa .

1. Bakeng sa lubrication ea chuck, sebelisa lubricant ho chuck kamehla ho etsa bonnete ba hore chuck e ntse e ka ba le ho nepahala ho phahameng nakong ea ho sisinyeha.Ela hloko ha u tlotsa.Ho tlotsa ka nepo ho ka etsa hore chuck ea pneumatic e hlolehe ho sebetsa ka mokhoa o tloaelehileng ha khatello ea moea e le tlase, matla a ho koala a fokotsehile, ho nepahala ha clamping ho fokola, moaparo ha oa tloaeleha kapa o tsitsitse, kahoo ela hloko ts'ebetso e nepahetseng ea lubrication ha u tlotsa .

2. Sebelisa grease ea molybdenum disulfide, hangata e ntšo, 'me u kenye mafura ka har'a nozzle ea chuck ho fihlela mafura a phalla ka holim'a mohlahare kapa lesoba le ka hare la chuck.Haeba chuck e sebetsa ka lebelo le phahameng ka nako e telele kapa e sebelisa ts'ebetso e thusang oksijene nako e telele, ho hlokahala hore ho be le lubrication e eketsehileng, 'me makhetlo a mangata a lubrication a tlameha ho fetoloa ho ea ka maemo a sebele a ho sebetsa.

3. Ka mor'a hore ts'ebetso e phethoe nako le nako, ho hlokahala hore u sebelise sethunya sa moea se nang le khatello e phahameng ho sebetsana le masala a lerōle ho chuck ka boeona le slideway.Ho khothalletsoa ho hloekisa mehlahare ea chuck likhoeli tse ling le tse ling tse 3-6 ho boloka bokaholimo bo hloekile ebile bo tlotsa.Hlahloba hore na likarolo li robehile 'me li tsofetse, 'me u li nkele sebaka haeba seaparo se tebile.Kamora ho hlahlojoa, mehlahare e lokela ho tlotsoa hantle le ho kenngoa pele e sebelisoa.

4. Lisebelisoa tse khethehileng kapa li-workpieces tse sa tloaelehang li hloka ho tlamisoa le ho sebetsoa ka li-chucks tse itseng.The standard laser pipe cutting chuck e loketse bakeng sa libopeho tsa symmetrical le tse koetsoeng.Haeba u e sebelisa ka matla ho koala li-workpieces tse sa tloaelehang kapa tse makatsang, e tla baka ho se tloaelehe ha chuck;haeba khatello ea phepelo ea moea ea chuck e phahame haholo, chuck e tla ba tlas'a khatello e phahameng kapa ka mor'a ho koala The chuck e boetse e thibela mosebetsi oa matsoho, e leng ho tla fokotsa bophelo ba chuck le ho baka mathata a kang ho tlosoa ho feteletseng.

5. Thibela tšepe e pepeneneng ea chuck ho mafome.Ho thibela mafome ke ntlha e ’ngoe ea bohlokoa.Ho rusa ha chuck ho tla fokotsa matla a ho koala 'me ha ho khone ho koala sekheo sa mosebetsi, se amang haholo ho nepahala le katleho ea tlhahiso.

Mokhoa o ka holimo ke mokhoa o ka sehloohong oa ho boloka mochine oa ho itšeha oa laser pipe.Ha e le hantle, tšebeliso e hlokolosi ea opareitara le mehato e tsitsitseng ea ts'ebetso ea basebetsi le tsona ke lintlha tsa bohlokoa bakeng sa ho boloka ts'ebetso ea mochine oa ho khaola liphaephe.

Nako ea poso: Jan-19-2023