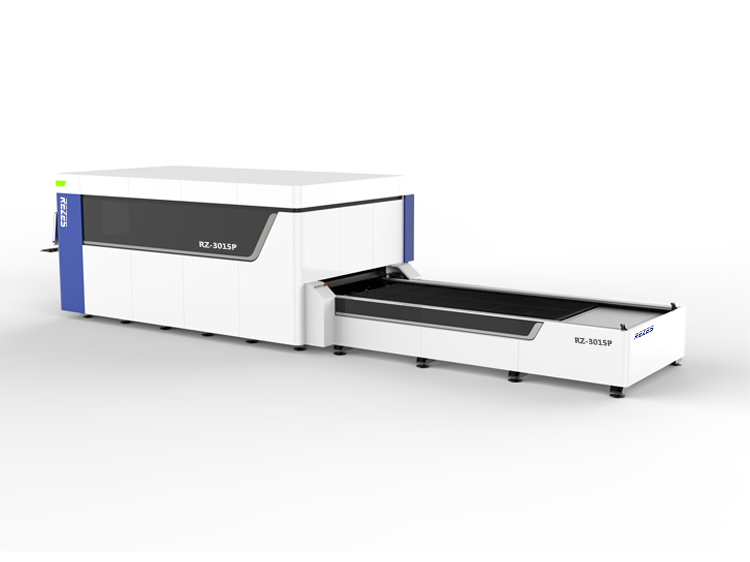

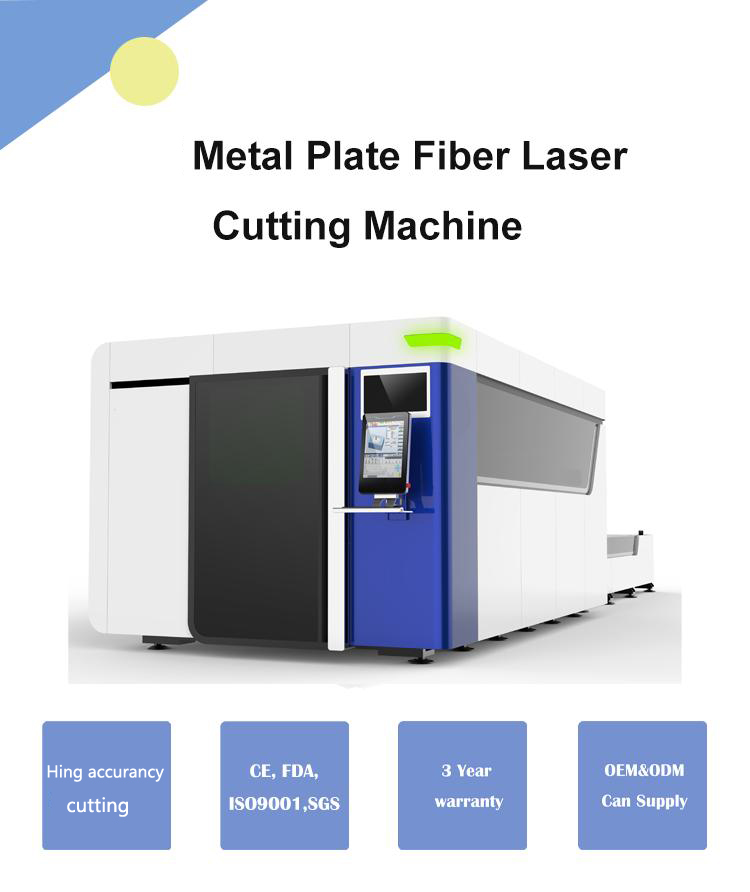

Mochini o Felletseng oa Sekoahelo sa Laser

Pontšo ea Sehlahisoa

Tekheniki parameter

| Kopo | Ho khaola Laser | Boitsebiso bo sebetsang | Tšepe |

| Sebaka sa ho Seha | 1500mm * 3000mm | Mofuta oa Laser | Fiber Laser |

| Laola Software | Cypcut | Letšoao la Hlooho ea Laser | Li-raytools |

| Servo Motor Brand | Enjene ea Yaskawa | Tlaleho ea Teko ea Mechini | Fanetsoe |

| Sebopeho sa Graphic se tšehelitsoe | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC kapa che | Ee |

| Lintlha tsa bohlokoa tsa ho rekisa | Ho nepahala ho phahameng | Boima ba 'mele | 4500kg |

| Mokhoa oa Ts'ebetso | boiketsetso | Boemo bo Nepahetseng | ± 0.05 limilimithara |

| botjha boemo bo nepahetseng | ± 0.03 limilimithara | Peak Acceleration | 1.8G |

| Liindasteri tse sebetsang | Lihotele, Mabenkele a Lintho tsa Moaho, Setsi sa Tlhahiso | Likarolo tsa moea | SMC |

| Mokhoa oa Ts'ebetso | leqhubu le tsoelang pele | Sebopeho | Sekoahelo se felletseng |

| Ho poma Lebelo | ho itshetlehile ka matla le botenya | Laola Software | Tubepro |

| Botenya ba ho Seha | 0-50 limilimithara | Guiderail Brand | HIWIN |

| Likarolo tsa motlakase | schneider | Nako ea tiisetso | 3 lilemo |

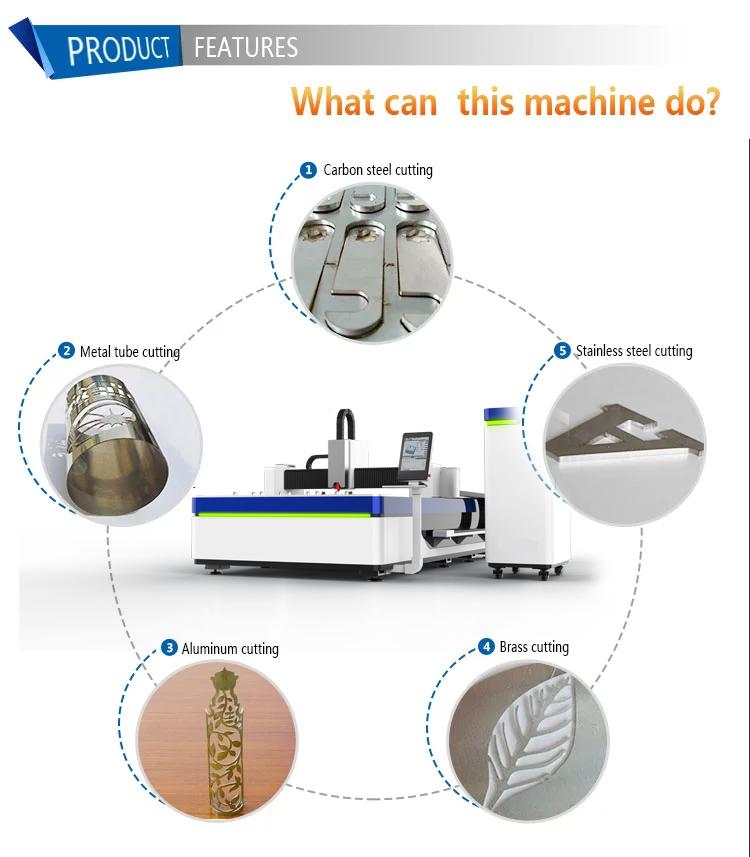

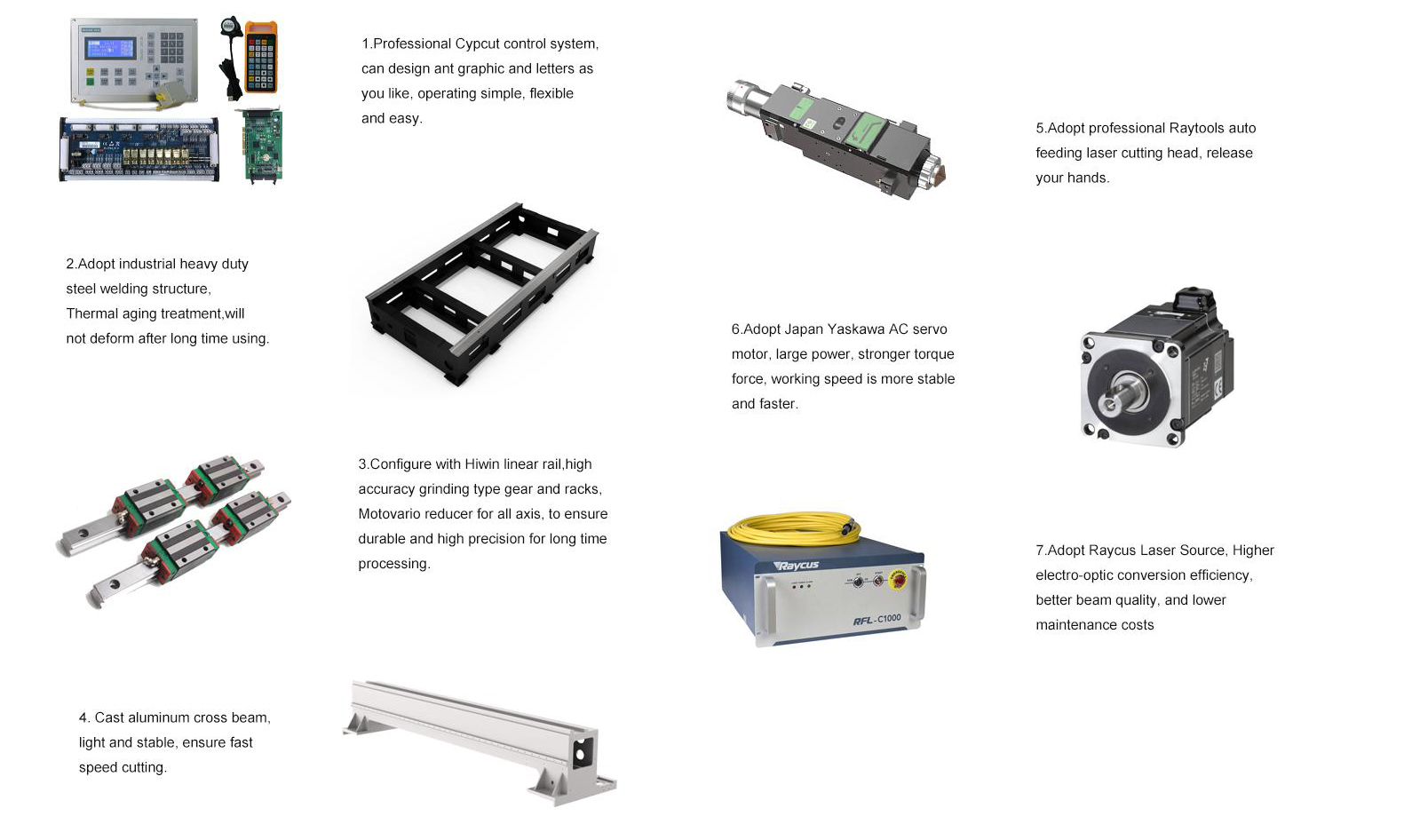

Likarolo tsa mochini

Video ea mochini

Mochini o Felletseng oa Sekoahelo sa Laser

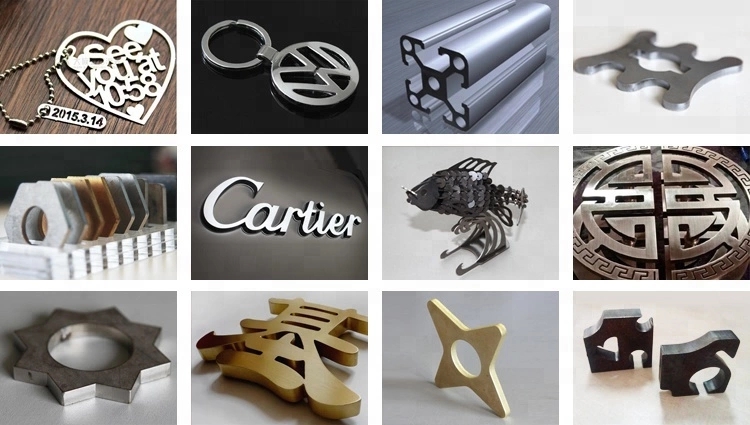

Ho khaola lisampole

Kopo

1. Indasteri ea likoloi

Mechini ea ho itšeha ea laser e sebelisoa likoahelong tse ka pele tsa koloi, tšepe ea pampiri ea koloi, liphaephe tsa ho ntša koloi, joalo-joalo, 'me li hloka ho sebetsoa ka mor'a ho etsa likhutlo tse ling tse feteletseng kapa li-burrs. Haeba ts'ebetso ea matsoho e sebelisoa, ho thata ho fihlela maemo a lakatsehang a ts'ebetso le ho nepahala.

2. Indasteri ea mokhabiso

Indasteri ea mokhabiso e hloka ho sebelisa litšoantšo tse ngata tse rarahaneng, 'me mochine oa ho itšeha oa laser o ka kopana le ts'ebeliso ea indasteri ena ka lebelo la ho itšeha ka potlako le ho itšeha habonolo,' me e tumme haholo har'a lik'hamphani tsa mokhabiso. Kamora ho rala lits'oants'o tse amehang, ho ka qotsoa ho kenya ntho e le 'ngoe feela.

3.Indasteri ea papatso

Mechini e Sehang ea Fiber Laser e sebelisoa haholo ho etsa Billboard, Papatso, Matšoao, Lipontšo, Litlhaku tsa Metal, Litlhaku tsa LED.

4.Lisebelisoa tsa ka tlung le indasteri ea li-kitchenware

Lisebelisoa tsa lapeng le tsa kichineng ha e le hantle li entsoe ka lipoleiti tse tšesaane. Pele ho ts'ebetso ea setempe le ho taka, mochini oa ho itšeha oa fiber laser o sebelisoa ho sebetsana le disampole ho hlahisa lihlahisoa tse ncha kapele. Lebelo la ho itšeha la lisebelisoa tsa ho sebetsana le laser le potlakile, e leng se ntlafatsang haholo ts'ebetso ea ts'ebetso. Ka nako e ts'oanang, lisebelisoa tsa ts'ebetso ea laser li na le ho nepahala ho phahameng, e leng ho ntlafatsang lihlahisoa tsa li-hoods le lisebelisoa tse tukang. Bakeng sa lihlahisoa tse ling tse nang le sebōpeho se khethehileng, mechine ea ho itšeha ea fiber laser e na le melemo e ikhethang, ho kenyelletsa lik'habote tsa kabo ea matla, lik'habote tsa ho kenya, joalo-joalo, tseo kaofela e leng tlhahiso e tloaelehileng ea lipoleiti tse tšesaane 'me li hloka bokhoni. Tšebeliso ea mechine ea ho itšeha ea laser e ka ntlafatsa haholo katleho.

5.Indasteri ea mechini ea temo

Ho na le mefuta e mengata ea likarolo tsa ts'ebetso ea letlapa bakeng sa lihlahisoa tsa mochini oa temo, 'me li nchafatsoa kapele. Likarolo tse tloaelehileng tsa lisebelisoa tsa tšepe tsa lihlahisoa tsa mochini oa temo hangata li sebelisa mokhoa oa ho phunya, o jang hlobo e ngata. Haeba ts'ebetso ea likarolo e ntse e lula ka tsela ea setso, e tla thibela ka matla ho nkeloa sebaka ha lihlahisoa. Litšobotsi tse feto-fetohang tsa laser lia bonahala. Ts'ebetso ea laser e ka hlokomela ho seha ha libopeho tse fapaneng tsa lipoleiti ka thuso ea software ea mananeo. Ho sebelisa laser processing ha ho na lebelo la ho sebetsa ka potlako feela, ts'ebetso e phahameng, le litšenyehelo tse tlase, empa hape ha ho hlokahale hore ho nkeloe hlobo kapa lisebelisoa, ho khutsufatsa nako ea ho lokisetsa tlhahiso. E ka boela ea tsamaisana le lebelo la ha sehlahisoa se nchafatsoa, 'me mokhoa o mocha o ka khaoloa ka ho taka hape le ho etsa mananeo. Ho bonolo ho elelloa ts'ebetso e tsoelang pele, nako ea phetoho ea lebone la laser e khuts'oane, 'me katleho ea tlhahiso e phahame. Li-workpieces tse fapaneng li ka kenngoa ka tsela e fapaneng. Ha workpiece e sebetsoa, likarolo tse phethiloeng li ka tlosoa 'me workpiece e lokelang ho sebetsoa e ka kenngoa ho hlokomela ts'ebetso e tšoanang.

6.Indasteri ea mechine ea kaho

Ka indasteri ea kaho mechine, faeba laser ho itšeha chitja masoba ka sebelisoa hafeela bophara ba workpiece lesoba chitja e moholo ho feta kapa lekana le botenya poleiti, 'me litlhoko tsa roughness le bophara ke ka hare ho bokgoni tiisetso ya mochine seha ha tobane le botenya e itseng poleiti. Laser e khaola thepa ka ho toba, e felisa mokhoa oa ho cheka le ho ntlafatsa katleho ea tlhahiso ea mosebetsi. Bakeng sa lisebelisoa tse ling tse nang le masoba a mangata, ts'ebetso ea matheba ea mochini oa ho cheka oa fiber laser e sebelisoa ho tseba hore na sekoti ke sefe, se bolokang nako ea ho beha sekoti bakeng sa ts'ebetso e latelang ea ho phunya, hape e boloka litšenyehelo tsa tlhahiso ea template ea ho cheka, e sa ntlafatse ts'ebetso ea tlhahiso feela, empa hape e ntlafatsa ho nepahala ha sehlahisoa.