Tse tharo ho Mochini o le Mong oa Welding oa Laser

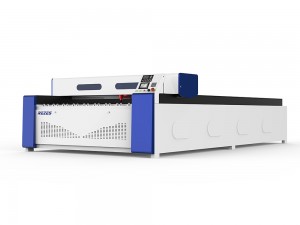

Pontšo ea Sehlahisoa

Tekheniki parameter

| Kopo | Laser Welding Cutting and Cleaning | Boitsebiso bo sebetsang | Lisebelisoa tsa tšepe |

| Letšoao la Mohloli oa Laser | Raycus/MAX/BWT | CNC kapa che | Ee |

| Pulse Width | 50-30000Hz | Focal Spot Diameter | 50μm |

| Matla a Phallo | 1500W/2000W/3000W | Laola Software | Ruida/Qilin |

| Bolelele ba Fiber | ≥10m | Wavelength | 1080 ±3nm |

| Setifikeiti | CE, ISO9001 | Sistimi ea ho pholisa | Pholiso ea metsi |

| Mokhoa oa Ts'ebetso | Tsoelang pele | Sebopeho | Tlhokomelo e tlase |

| Tlaleho ea Teko ea Mechini | Fanetsoe | Tlhahlobo ea video e tsoang | Fanetsoe |

| Sebaka sa Tšimoloho | Jinan, Profinseng ea Shandong | Nako ea tiisetso | 3 lilemo |

Video ea mochini

Sebopeho sa Three in One Laser Welding Machine

1. Matla a phahameng a matla le matla a phahameng a ho cheselletsa

Bongata ba matla a laser beam ea mochini o tsoelang pele oa welding oa fiber laser o phahame haholo, o ka qhibilihang lisebelisoa tsa tšepe kapele mme oa theha weld e tiileng. Matla a tjheseletsa a ka lekana kapa a phahame ho feta a thepa ya motswadi.

2. Li-welds tse ntle, ha ho na ts'ebetso ea morao-rao e hlokahalang

Li-welds tse hlahisoang ke laser welding li boreleli ebile li tšoana, ntle le ho sila kapa ho belisoa ho eketsehileng, e leng ho fokotsang haholo litšenyehelo tsa ho sebetsa ka morao. E loketse haholo liindasteri tse nang le litlhoko tse phahameng tsa ponahalo ea welding, joalo ka lihlahisoa tsa tšepe tse sa hloekang, indasteri ea mekhabiso ea tšepe, joalo-joalo.

3. Lebelo la tjheseletsa le potlakileng le katleho e ntlafetseng ya tlhahiso

Ha ho bapisoa le mekhoa e tloaelehileng ea ho tjheseletsa (joalo ka TIG / MIG welding), lebelo la mechine e tsoelang pele ea ho tjheseletsa ka laser e ka eketsoa ka makhetlo a 2-10, e ntlafatsa haholo katleho ea tlhahiso, 'me e loketse maemo a tlhahiso ea bongata.

4. Sebaka se senyenyane se amehileng ke mocheso le deformation e nyenyane

Ka lebaka la litšobotsi tse lebisang tlhokomelo ea laser, mocheso oa mocheso sebakeng sa welding o monyenyane, o fokotsa ho senyeha ha mocheso oa mochine oa mosebetsi, haholo-holo o loketseng likarolo tse nepahetseng tsa welding, tse kang likarolo tsa elektronike, lisebelisoa tsa bongaka, joalo-joalo.

5. Na weld mefuta e fapaneng ya thepa ea tšepe, ka mefuta e fapaneng ya dikopo

E sebetsa ho tšepe e sa hloekang, tšepe ea carbon, alloy ea aluminium, koporo, alloy ea nickel, alloy ea titanium le lisebelisoa tse ling le lisebelisoa tsa tsona, tse sebelisoang haholo ho etsa likoloi, ho sebetsana le letlapa la tšepe, sefofane, lisebelisoa tsa elektroniki, lisebelisoa tsa bongaka le liindasteri tse ling.

6. Tekanyo e phahameng ea automation, e ka kopanngoa le welding ea robot

Mochini o tsoelang pele oa fiber laser welding o ka kopanngoa le liroboto le mekhoa ea CNC ho finyella welding e ikemetseng, ho ntlafatsa boemo ba tlhahiso e bohlale, ho fokotsa ho kenella ka letsoho, le ho ntlafatsa ts'ebetso ea tlhahiso le botsitso.

7. Ts'ebetso e bonolo le litšenyehelo tse tlase tsa tlhokomelo

Thepa e amohela sebopeho sa ho ama liindasteri, li-parameter tse feto-fetohang, le ts'ebetso e bonolo; laser fiber e na le bophelo bo bolelele (hangata ho fihlela lihora tse 100,000) le litšenyehelo tse tlase tsa tlhokomelo, tse fokotsang haholo litšenyehelo tsa tšebeliso ea likhoebo.

8. Ts'ehetsa mekhoa e ts'oaroang ka letsoho le e ikemetseng

U ka khetha hlooho ea ho tjheseletsa ka letsoho ho finyella welding e tenyetsehang, e loketseng li-workpieces tse kholo kapa tse sa tloaelehang; e ka boela ea sebelisoa le benche ea mosebetsi e ikemetseng kapa roboto ho finyella litlhoko tsa tlhahiso ea mohala oa kopano.

9. Motsoalle oa tikoloho le o bolokehileng, ha ho na slag ea welding, ha ho na mosi le lerōle

Ha ho bapisoa le li-welding tsa setso, ho cheselletsa ka laser ha ho hlahise mosi o mongata, litlhase le slag ea ho cheselletsa, e baballang tikoloho ebile e bolokehile, 'me e kopana le litekanyetso tsa sejoale-joale tsa tlhahiso e tala ea indasteri.

Mehlala ea welding

Tshebeletso

1. Litšebeletso tse ikhethileng:

Re fana ka customized faeba laser tjheseletsa metjhini, tloaelo etselitsoe le entsoe ho ea ka litlhoko tsa bareki. Ebang ke litaba tsa welding, mofuta oa thepa kapa lebelo la ho sebetsa, re ka li fetola le ho li ntlafatsa ho latela litlhoko tse khethehileng tsa moreki.

Litherisano tsa 2.Pre-sales le tšehetso ea tekheniki:

Re na le sehlopha se nang le boiphihlelo sa baenjiniere ba ka fang bareki boeletsi ba litsebi tsa pele ho thekiso le tšehetso ea tekheniki. Ebang ke khetho ea lisebelisoa, keletso ea kopo kapa tataiso ea tekheniki, re ka fana ka thuso e potlakileng le e sebetsang hantle.

3.Quick karabo ka mor'a thekiso

Fana ka tšehetso ea tekheniki ka mor'a thekiso e potlakileng ho rarolla mathata a fapaneng ao bareki ba kopanang le ona nakong ea ts'ebeliso.

LBH

P: Ke lisebelisoa life tse ka chesetsoang ka mochini oa welding oa laser?

A: Mochini o tsoelang pele oa fiber laser welding o loketse mefuta e sa tšoaneng ea lisebelisoa tsa tšepe, tse kang: tšepe e sa hloekang, carbon steel, alloy aluminium, koporo, nickel alloy, titanium alloy, galvanized sheet, joalo-joalo.

Bakeng sa litšepe tse khanyang haholo (tse kang koporo, aluminium), hoa hlokahala ho khetha matla a laser a nepahetseng le liparamente tsa welding ho fumana liphetho tse ntle tsa welding.

P: Botenya ba ho tjheseletsa ka laser ke bofe?

A: The tjheseletsa botenya itšetlehile ka matla laser.

P: Na welding ea laser e hloka khase e sireletsang?

A: E, hangata ho hlokahala khase e sireletsang (argon, naetrojene kapa khase e tsoakiloeng), 'me mesebetsi ea eona e kenyelletsa:

- Thibela oxidation nakong ea welding le ho ntlafatsa boleng ba weld

- Fokotsa tlhahiso ea weld porosity le ho matlafatsa matla a ho tjheseletsa

- Khothalletsa ho tiisa letamo le ho etsa hore weld e be boreleli

Q: Phapang ke efe pakeng tsa mochini oa tjheseletsa oa laser o nang le letsoho le mochini o tjheseletsang laser o othomathike?

A: Handheld: E loketse ts'ebetso e feto-fetohang, e ka cheselletsa libopeho tse sa tloaelehang le lisebelisoa tse kholo tsa mosebetsi, tse loketseng tlhahiso ea batch e nyane le e mahareng.

Automation: E loketse tlhahiso e kholo, e emeng, e ka kopanya matsoho a robotiki le li-workstations tsa welding ho ntlafatsa katleho ea tlhahiso.

P: Na deformation e tla etsahala nakong ea welding ea laser?

A: Ha ho bapisoa le mekhoa ea khale ea ho tjheseletsa, laser welding e na le mocheso o fokolang oa mocheso le sebaka se senyenyane se amehileng ke mocheso, 'me hangata ha se hlahise deformation e hlakileng. Bakeng sa lisebelisoa tse tšesaane, li-parameter li ka fetoloa ho fokotsa ho kenya mocheso le ho fokotsa deformation.

P: Bophelo ba tšebeletso ea lisebelisoa ke nako e kae?

A: Bophelo ba khopolo-taba ea laser fiber bo ka fihla "lihora tse 100,000", empa bophelo ba sebele bo itšetlehile ka tikoloho ea tšebeliso le tlhokomelo. Ho boloka pholile e ntle le ho hloekisa kamehla likarolo tsa optical ho ka eketsa bophelo ba lisebelisoa.

P: Ke lintlha life tse lokelang ho eloa hloko ha u reka mochini oa welding oa laser?

A: - Netefatsa thepa le botenya bo hlokahalang, 'me u khethe matla a loketseng

- Ak'u nahane hore na ho hlokahala welding e ikemetseng ho ntlafatsa katleho ea tlhahiso

- Khetha moetsi ea tšepahalang ho netefatsa boleng ba lisebelisoa le tšebeletso ea ka mor'a thekiso

- Utloisisa hore na ho hlokahala litsamaiso tse khethehileng tsa ho pholisa kapa tsa tšireletso