Mofuta oa liroboto Mochini oa Welding oa Laser

Pontšo ea Sehlahisoa

Tekheniki parameter

| Roboto ea li-axis tse tšeletseng | Tuling | Likaroloana tsa mantlha | Mohloli oa Laser |

| Tšebeliso | Weld Metal | Max. Matla a Phallo | 2000W |

| Boitsebiso bo sebetsang | Tšepe | Cnc Kapa Che | Ee |

| Mokhoa oa ho Pholisa | Pholiso ea Metsi | Motlakase le Pneumatic Systems | Schneider |

| Wavelength | 1090Nm | Matla a Laser | 1000w / 1500w / 2000w |

| Boima (Kg) | 600 Kg | Setifikeiti | Ce, Iso9001 |

| Likaroloana tsa mantlha | Fiber Laser Source, Fiber, Tšoara Laser Welding Hlooho | Lintlha tsa bohlokoa tsa ho rekisa | Ho Nepaha Ho Phahameng |

| Mosebetsi | Metal Karolo Laser Welding | Bolelele ba Fiber | ≥10m |

| Liindasteri tse sebetsang | Lihotele, Mabenkele a Liphahlo, Mabenkele a Thepa ea Moaho | Likaroloana tsa mantlha | Mohloli oa Laser |

| Mokhoa oa ho sebetsa | Pulsed | Ka mor'a Tšebeletso ea Warranty | Tšehetso ea Inthaneteng |

| Focal Spot Diameter | 50μm | Boholo ba Tšireletso | 1730 limilimithara |

| Tlhahlobo ea Video e Tsoang | Fanetsoe | Sebopeho sa Graphic se tšehelitsoe | Ai, Plt, Dxf, Dwg, Dxp |

| Sebaka sa Tšimoloho | Jinan, Profinseng ea Shandong | Nako ea Tiisetso | Lilemo tse 3 |

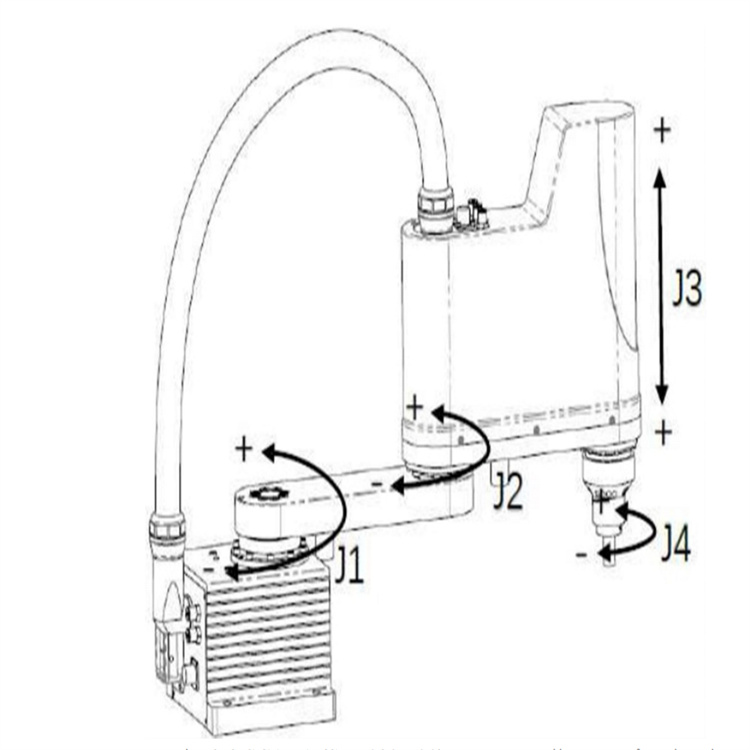

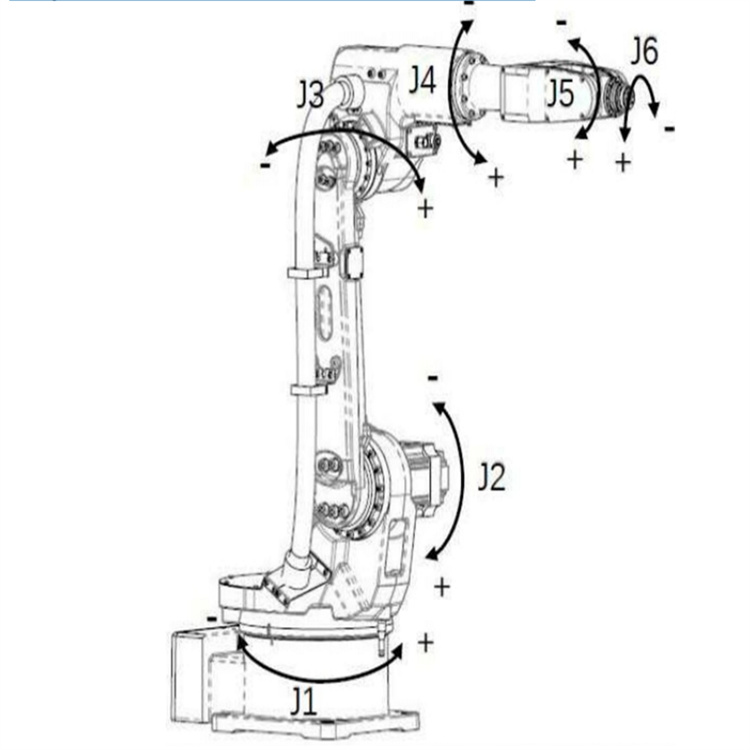

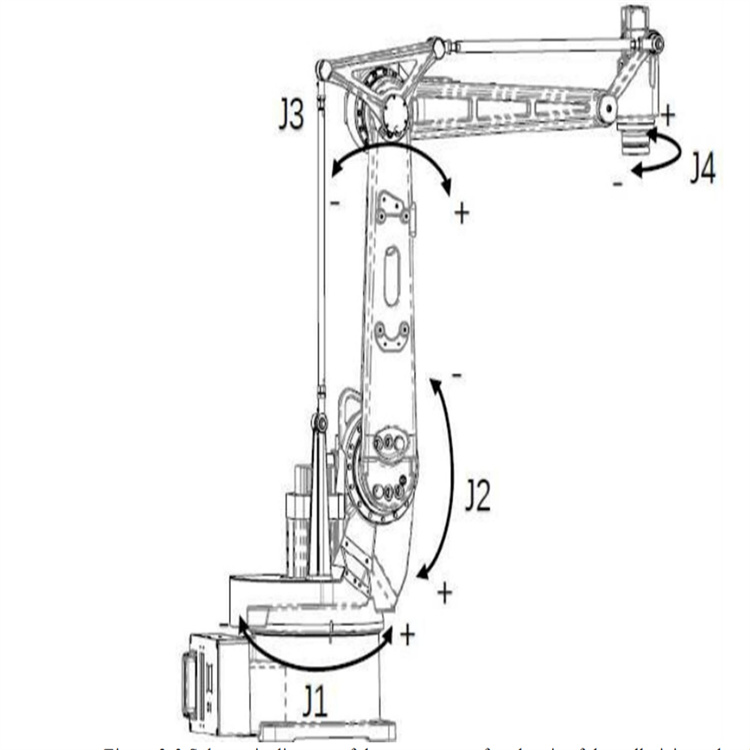

Letsoho la roboto

Sebaka sa liroboto e ka ba sekhechana sa rotary kapa axis ea phetolelo, mme mokhoa oa ts'ebetso oa axis o khethoa ke sebopeho sa mochini. Sebaka sa liroboto se arotsoe ka axis e tsamaeang ea 'mele oa roboto le axis e kantle. The shaft kantle e arotsoe ka sliding tafole le positioner. Ntle le ha ho boletsoe ka tsela e 'ngoe, axis ea roboto e bua ka axis e tsamaeang ea' mele oa roboto.

Liroboto tsa Turing li arotsoe ka mefuta e meraro ea liroboto tsa indasteri:

Roboto ea li-axis tse tšeletseng tsa indasteri: ho kenyelletsa le lilepe tse tšeletseng tsa ho potoloha

SCARA: e na le lilepe tse tharo tsa ho potoloha le li-axis tse le 'ngoe tsa phetolelo

Palletizing manipulator: ho kenyelletsa le li-shafts tse 'nè tse potolohileng Motsamao o kopanetsoeng oa roboto o bontšoa setšoantšong.

Ts'ebeliso ea mochini oa tjheseletsa oa liroboto

1.Sebaka sa Tlhahiso ea Mechini

Ka ho matlafala ha mesebetsi ea li-welding indastering ea tlhahiso ea mechini, ts'ebetso ea ho cheseletsa e na le maemo a tlase a ts'ebetso le mahlaseli a maholo a mocheso, e leng mosebetsi o kotsi haholo. Ho boetse ho na le lisebelisoa tse ngata tse kholo indastering ea ho etsa mechini, e leng ho eketsang bothata ba ho cheselletsa. , Roboto ea Welding ke sesebelisoa sa mochini o ikemetseng se etsang mosebetsi oa ho cheselletsa, se lokollang matla a basebetsi mme se thusa ho ntlafatsa boemo ba boiketsetso lefapheng la tlhahiso ea mechini.

2.Automobile le likoloi likarolo :

Lilemong tsa morao tjena, e le ho finyella litlhoko tsa sechaba, indasteri ea likoloi e bontšitse tsoelo-pele e fapaneng. Welding ea setso ha e khone ho fihlela litlhoko tse phahameng tsa ho tjheseletsa ha ho etsoa likarolo tsa likoloi le likoloi. , The welding seam e ntle ebile e tiile. Lithupelong tse ngata tsa sejoale-joale tsa tlhahiso ea likoloi, ho theiloe likhoele tsa kopano ea liroboto tsa welding.

3. Thepa ea elektronike:

Tšimo ea lisebelisoa tsa elektroniki e na le litlhoko tse phahameng haholo bakeng sa boleng ba welding. Ka tlhokahalo e ntseng e eketseha ea lisebelisoa tsa elektroniki sechabeng, lisebelisoa tsa elektroniki le tsona li tobane le mathata a maholo ha li ntse li hola ka potlako. Liroboto tsa welding li ka tsitsisa boleng ba welding ha li ntse li netefatsa katleho ea tlhahiso. Thepa e nepahetseng ea tjheseletsa ea thepa e phahame ka makhetlo a mararo ho isa ho a mane ho feta ea mosebetsi oa matsoho.

4. Sepakapaka:

Sebopeho sa sefofane, ho na le likarolo tse ka bang 1 000 tsa 'mele oa ho cheselletsa, 'me likarolo tse ka bang 10 000 li ameha. Boholo ba likarolo tsa bohlokoa tse jarang moroalo oa sefofane li sebelisa lisebelisoa tse cheselitsoeng. 'Mele oa sefofane o tlas'a khatello e kholo nakong ea sefofane, kahoo ho tjheseletsa Litlhoko li batla li le thata,' me roboto ea ho tjheseletsa e ka khona ho beha mekhoa ea ho tjheseletsa ka mokhoa o itekanetseng oa ho latela seam ho latela theknoloji ho tsamaisa sebopeho sa sefofane ka nepo.

Tlhokomelo ea mochine

- Mokhoa oa ho fepa ka terata. Ho kenyeletsoa hore na sebaka sa ho fepa ka terata ke se tloaelehileng, hore na kotopo ea phepelo ea terata e senyehile, le hore na ho na le alamo e sa tloaelehang; Ebang phallo ea khase e tloaelehile; Hore na sistimi ea ts'ireletso ea toche ea welding e tloaelehile. (Ho thibetsoe ho koala toche ea tjheseletsa bakeng sa mosebetsi oa ts'ireletso ea ts'ireletso); Ho sa tsotellehe hore na mokhoa oa ho potoloha ha metsi o sebetsa ka mokhoa o tloaelehileng; teko ea TCP (e khothaletsoa ho bokella lenaneo la tlhahlobo le ho le tsamaisa ka mor'a ts'ebetso e 'ngoe le e' ngoe)

2. Tlhahlobo le tlhokomelo ea beke le beke

1. Hlakola axis e 'ngoe le e 'ngoe ea roboto; Hlahloba ho nepahala ha TCP; Sheba boemo ba oli e setseng. ;Lekola hore na sebaka sa zero sa axis ka 'ngoe ea roboto se nepahetse; Hloekisa sefe ka mor'a tanka ea metsi ea mochini oa tjheseletsa. Hloekisa sefe moo ho kenang moea o hatelitsoeng; Hloekisa litšila molomong oa toche ea tjheseletsa ho qoba ho koala potoloho ea metsi; Hloekisa mokhoa oa ho fepa ka terata, ho kenyeletsoa lebili la terata, lebili la terata le tšupu e tataisang ea terata; Sheba hore na sephutheloana sa hose le terata ea tataiso li senyehile kapa li robehile. (Ho kgothaletswa ho tlosa sephutheloana sa hose kaofela le ho se hloekisa ka moea o hatelitsoeng); Hlahloba hore na tsamaiso ea ts'ireletso ea toche ea welding e tloaelehile le hore na konopo ea ka ntle ea tšohanyetso ea tšohanyetso e tloaelehile.