Mini Portable Laser Machine bakeng sa ho itšeha, ho tjheseletsa le ho hlwekisa

Pontšo ea Sehlahisoa

Tekheniki parameter

| Boemo | E ncha | Likaroloana tsa mantlha | Mohloli oa Laser |

| Tšebeliso | Weld Metal | Max. Matla a Phallo | 2000W |

| Boitsebiso bo sebetsang | Tšepe | Cnc Kapa Che | Ee |

| Mokhoa oa ho Pholisa | Pholiso ea Metsi | Laola Software | Ruida/Qilin |

| Pulse Width | 50-30000Hz | Matla a Laser | 1000w / 1500w / 2000w |

| Boima (Kg) | 300 Kg | Setifikeiti | Ce, Iso9001 |

| Likaroloana tsa mantlha | Fiber Laser Source, Fiber, Tšoara Laser Welding Hlooho | Lintlha tsa bohlokoa tsa ho rekisa | Ho Nepaha Ho Phahameng |

| Mosebetsi | Metal Karolo Laser Welding | Bolelele ba Fiber | ≥10m |

| Liindasteri tse sebetsang | Lihotele, Mabenkele a Liphahlo, Mabenkele a Thepa ea Moaho | Likaroloana tsa mantlha | Phepelo ea Laser |

| Mokhoa oa ho sebetsa | Pulsed | Ka mor'a Tšebeletso ea Warranty | Tšehetso ea Inthaneteng |

| Focal Spot Diameter | 50μm | Wavelength | 1080 ±3nm |

| Tlhahlobo ea Video e Tsoang | Fanetsoe | Sebopeho sa Graphic se tšehelitsoe | Ai, Plt, Dxf, Dwg, Dxp |

| Sebaka sa Tšimoloho | Jinan, Profinseng ea Shandong | Nako ea Tiisetso | Lilemo tse 3 |

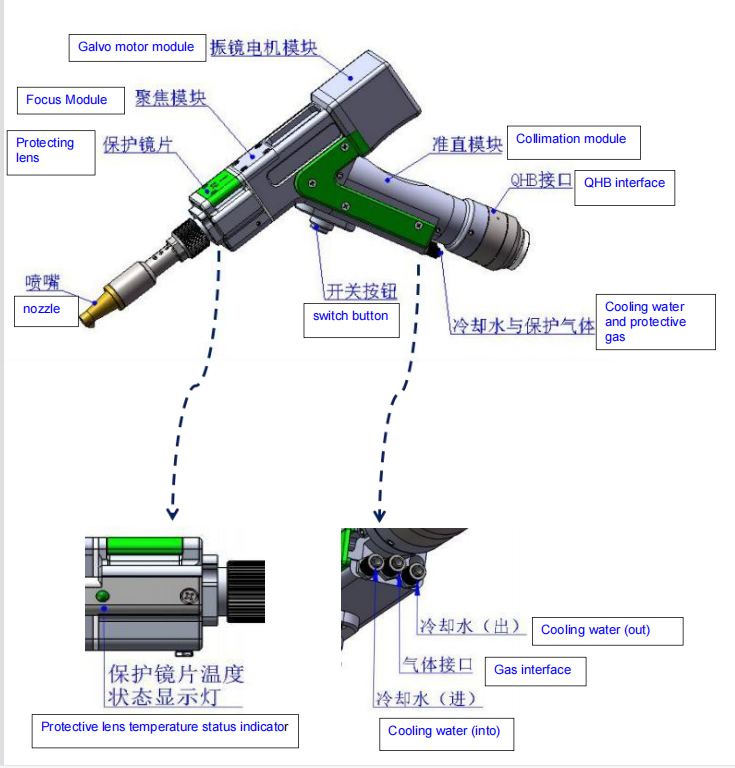

Likarolo tse ka Sehloohong bakeng sa Mochini

Mosebetsi o ka sehloohong oa mochine

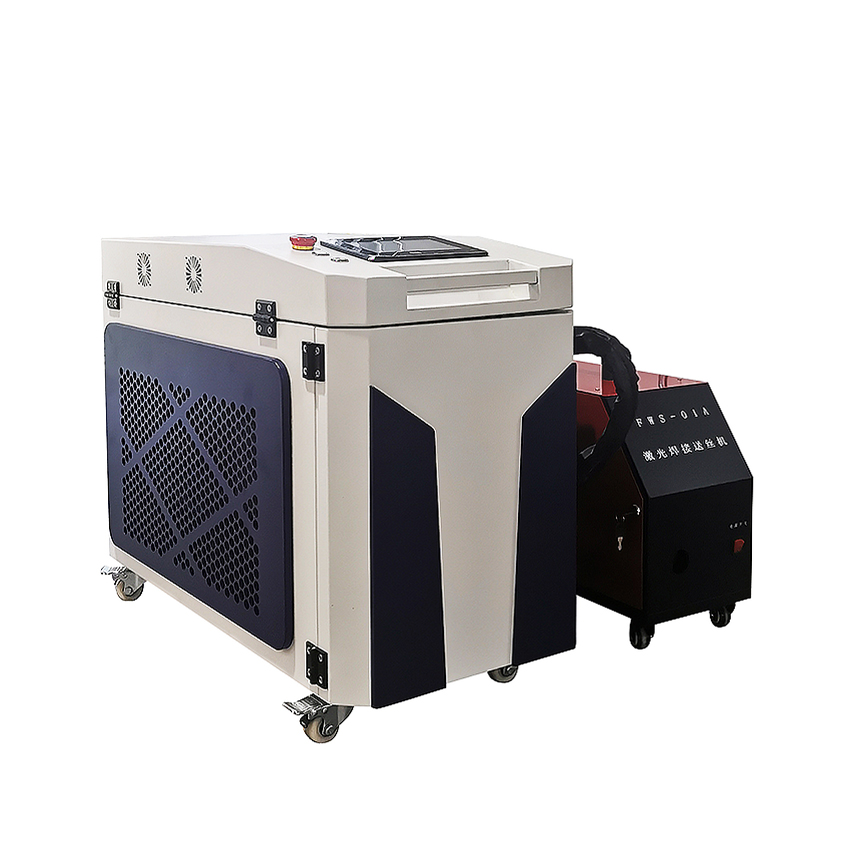

Mochini oa tharo-in-one oa laser welding le mochini oa ho hloekisa o ka khaola, oa cheselletsa le ho hloekisa litšepe ntle le ho reka lisebelisoa tse ngata tsa laser ka thoko. E loketse bakeng sa ho tjheseletsa tšepe e sa hloekang le li-alloys tsa aluminium, hape e ka tjheseletsa tšepe ea carbon, li-alloys tsa titanium, joalo-joalo, hape e ka sebelisoa bakeng sa ho cheselletsa. Ho tlosa mafome le ho seha tšepe ka letsoho. Bakeng sa ho hloekisa mafome a tšepe, pente, oli le liaparo, ho boloka litšenyehelo le sebaka.

E ka tjheseletsa lipoleiti tse fapa-fapaneng tsa tšepe le liphaephe, haholo-holo a loketse bakeng sa tjheseletsa tšepe e sa hloekang, khauta, silevera, koporo, lakane masenke, lakane aluminium, maqephe a sa tšoaneng alloy, litšepe tse sa tloaelehang le lisebelisoa tse ling.

Ho hloekisa ka holim'a patina ea koporo, peipi ea tšepe holim'a oxide le ho hloekisa litšila, ho senya seporo.

E sebelisoa haholo lipontšong tsa papatso, lihlahisoa tsa hardware, likarolo tsa koloi, limpho tsa mesebetsi ea matsoho le liindasteri tse ling, li ka sebelisoa bakeng sa ho cheselletsa carbon steel, tšepe e sa hloekang, titanium, aluminium le lisebelisoa tse ling tsa tšepe.

Mabapi le tšebeliso ea mochine

1.Sebopeho sa Sehlahisoa

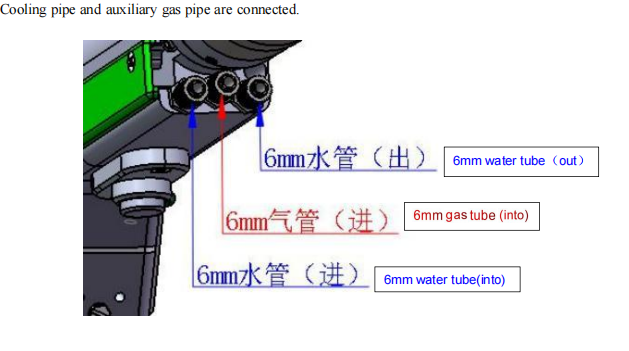

Khokahano ea 2.Pipe

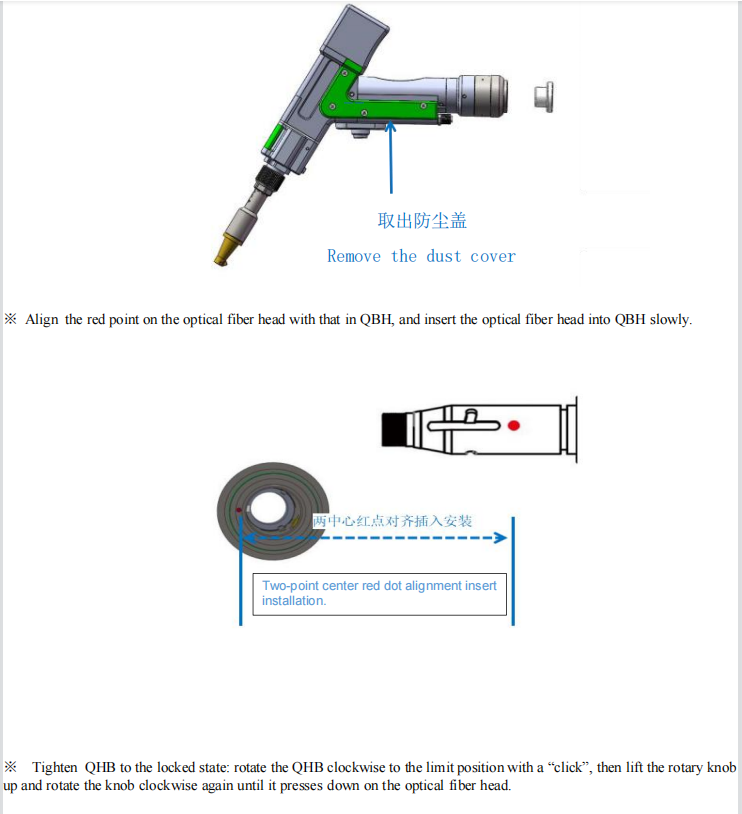

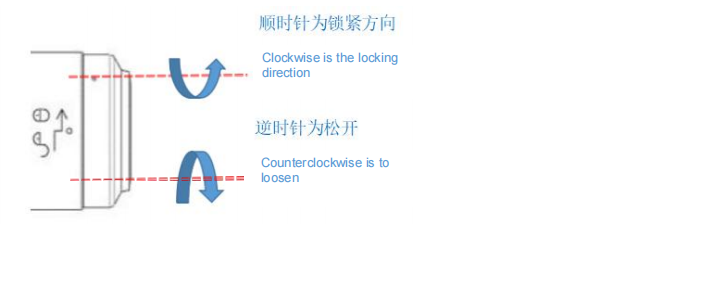

3.Fiber input input

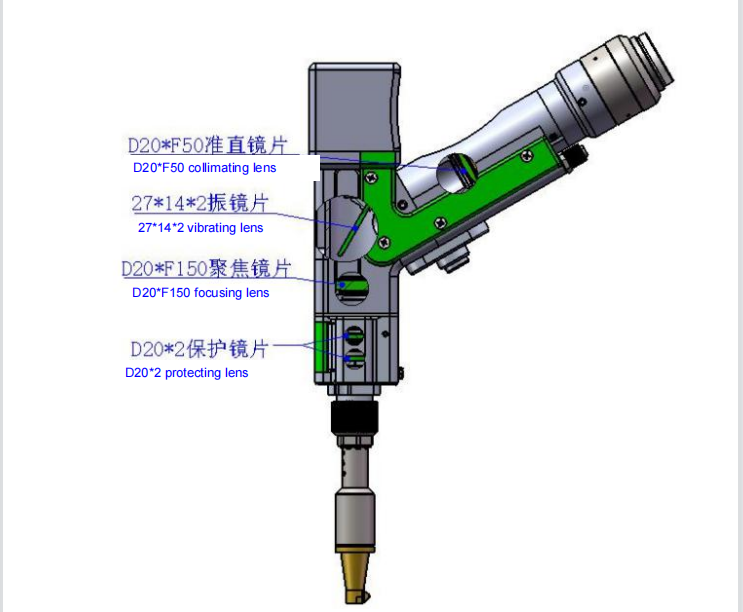

Tlhokomelo ea hlooho ea Laser

- Lense ea laser ea fiber:

Mokhoa oa ts'ebetso le litemoso: Sesebelisoa: liatlana tse se nang lerole kapa menoana e se nang lerole, swab ea k'hothone e se nang lerōle, joala ba isopropy le moea o hatelitsoeng o omeletseng o ka makotikoting. Fafatsa joala ba isopropyl holim'a sesepa sa k'hothone se se nang lerole, etsa hore lense e shebane le mahlo a hao, butle-butle u phunye lehlakoreng la lense ka monoana o motona le monoana oa letsoho la letsoho le letšehali, hlakola bokapele le ka morao ea lense ka tsela e le 'ngoe ho tloha ho le letšehali ho ea ho le letona kapa ho tloha holimo ho ea tlaase ka sesepa sa k'hothone se se nang lerole se tšoaroang ka letsohong le letona (hopola hore u se ke ua hlakola lense ho qoba lense le ho omisa lense), moea o hloekileng o hatelitsoeng ho netefatsa hore ha ho lerōle lenseng.

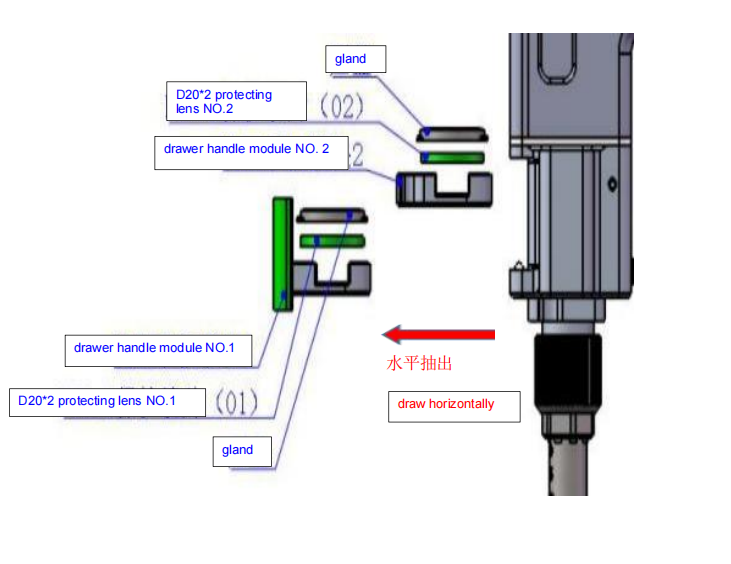

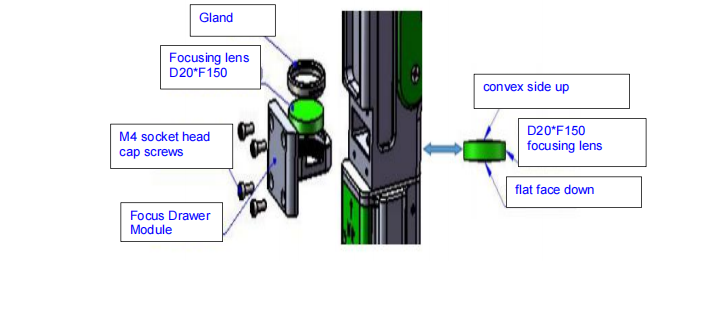

Ho qhekella ha lense e tsepamisitseng maikutlo:

Sesebelisoa: 2mm e ka hare ea hexagon wrench, swab e hloekileng ea k'hothone, tape ea joala le masking Ho kopanya le ho qhaqhoa ha lense ho lokela ho sebetsoa ka matsoho a apereng liatlana tse se nang lerole kapa lintlha tsa menoana sebakeng se hloekileng.

Mehato ea 1: lokolla M4 screw ka 2mm ka hare hexagon wrench. Mohato oa 2: ntša mojuleng oa ho tsepamisa maikutlo ka ho otloloha Mohato oa 3: tiisa boema-kepe ka theipi ea masking ho thibela lerōle ho kena ka mokoting ho baka tšilafalo. Mohato oa 4: sekoahelo se hatelloa ka bonolo 'me se pota-potiloe ka 90 °. Lulahanya libaka tse peli tsa convex le menyetla e letšehali le e nepahetseng. Ntša sekoahelo holimo 'me lense ea tšireletso e ka fetoloa. (Tlhokomeliso: kenya lense ka lehlakoreng la concave le convex.)

Ho qhaqhoa ha lense e sireletsang

Ho kopanya le ho qhaqhoa ha lense ho lokela ho sebetsoa ka matsoho a roetseng liatlana tse se nang lerole kapa lintlha tsa menoana sebakeng se hloekileng.

Mehato: Fetola khalase e sireletsang 01: Mohato oa 1: tšoara mahlakore ka bobeli a mojule oa 1 oa drawer e tala ka letsoho 'me u ntše lense e sireletsang ka tsela e tšekaletseng. Hlokomela lerōle, tiisa boema-kepe bo pepesitsoeng ka har'a sekoti ka theipi ea masking ho emisa ho kena ha lerōle ka mokoting ebe o nkela khalase e sireletsang sebaka. Mohato oa 2: sekoahelo se hatelloa ka bonolo 'me se potoloha 90 °. E lokolle ha mahlakore a mabeli a ikamahanya le li-notch tse peli. Ntša sekoahelo 'me u fetole lense e sireletsang. Fetola khalase e sireletsang 02: Mohato oa 1: Ntša mojule oa 1 oa drawer e tala 'me u ntše lense e sireletsang ka holimo. Ela hloko lerōle, koala kou e pepesitsoeng holim'a sekoti ka masking tape ho emisa ho kena ha lerōle ka mokoting ebe u nkela khalase e sireletsang sebaka. Mohato oa 2: sekoahelo se hatelloa ka bonolo 'me se potoloha 90 °. E lokolle ha mahlakore a mabeli a ikamahanya le li-notch tse peli. Ntša sekoahelo 'me u fetole lense e sireletsang.