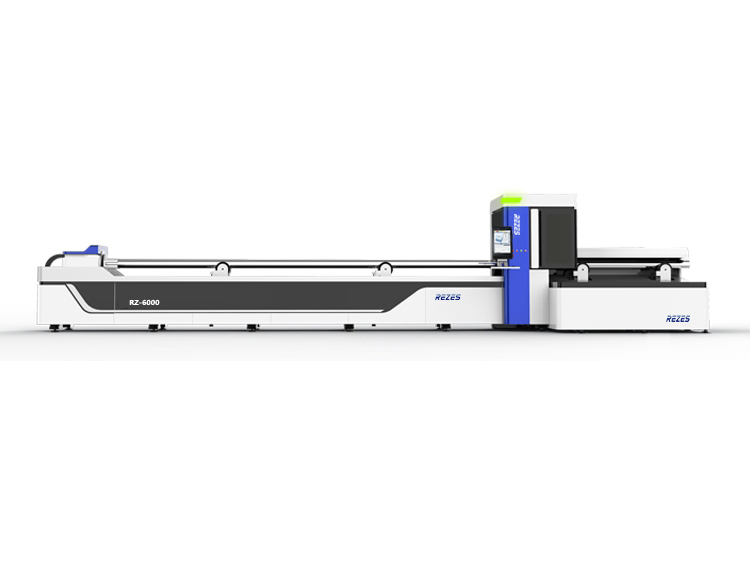

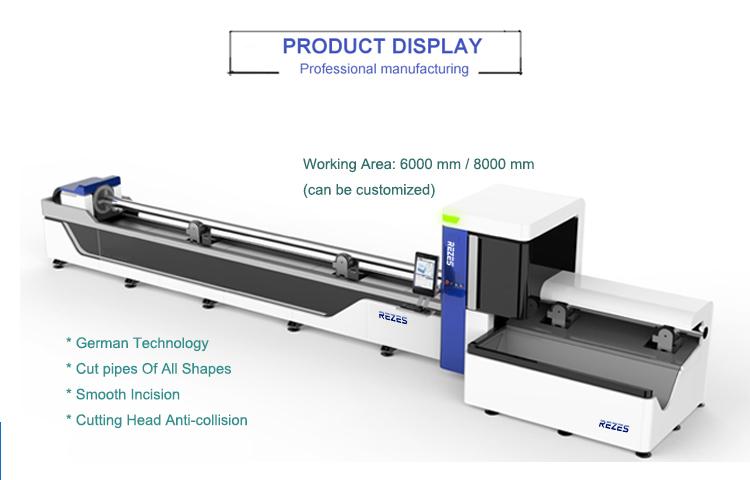

Metal Tube & Pipe Laser Cutting Machine

Pontšo ea Sehlahisoa

Tekheniki parameter

| Kopo | Ho khaola Laser | Boitsebiso bo sebetsang | Tšepe |

| Boemo | E ncha | Mofuta oa Laser | Fiber Laser |

| Laola Software | Cypcut | Letšoao la Hlooho ea Laser | Li-raytools |

| Penumatic chuck | 20-350 limilimithara | Bolelele ba ho Seha | 3m/6m |

| Servo Motor Brand | Enjene ea Yaskawa | Mohloli oa laser | IPG Raycus MAX JPT |

| Sebopeho sa Graphic se tšehelitsoe | AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC kapa che | Ee |

| Lintlha tsa bohlokoa tsa ho rekisa | Boemo bo Phahameng ba Tšireletso | Warranty ea likarolo tsa mantlha | Likhoeli tse 12 |

| Mokhoa oa Ts'ebetso | boiketsetso | Boemo bo Nepahetseng | ± 0.05 limilimithara |

| botjha boemo bo nepahetseng | ± 0.03 limilimithara | Peak Acceleration | 1.8G |

| Liindasteri tse sebetsang | Lihotele, Mabenkele a Lintho tsa Moaho, Setsi sa Tlhahiso | Likarolo tsa moea | SMC |

| Mokhoa oa Ts'ebetso | leqhubu le tsoelang pele | Sebopeho | Sethala se habeli |

| Ho poma Lebelo | ho itshetlehile ka matla le botenya | Laola Software | Tubepro |

| Likaroloana tsa mantlha | Laser jenereithara | Guiderail Brand | HIWIN |

| Likarolo tsa motlakase | schneider | Nako ea tiisetso | 3 lilemo |

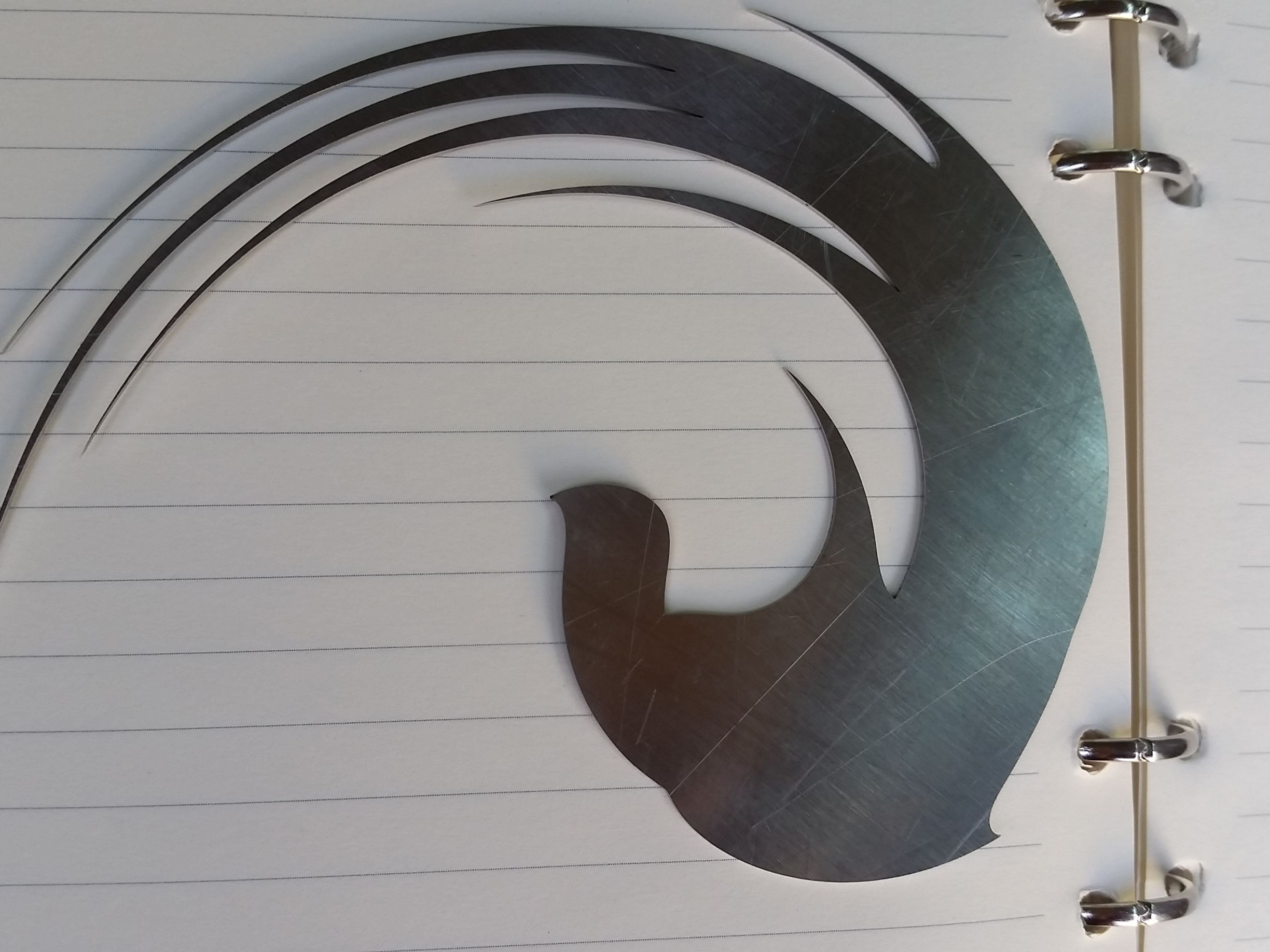

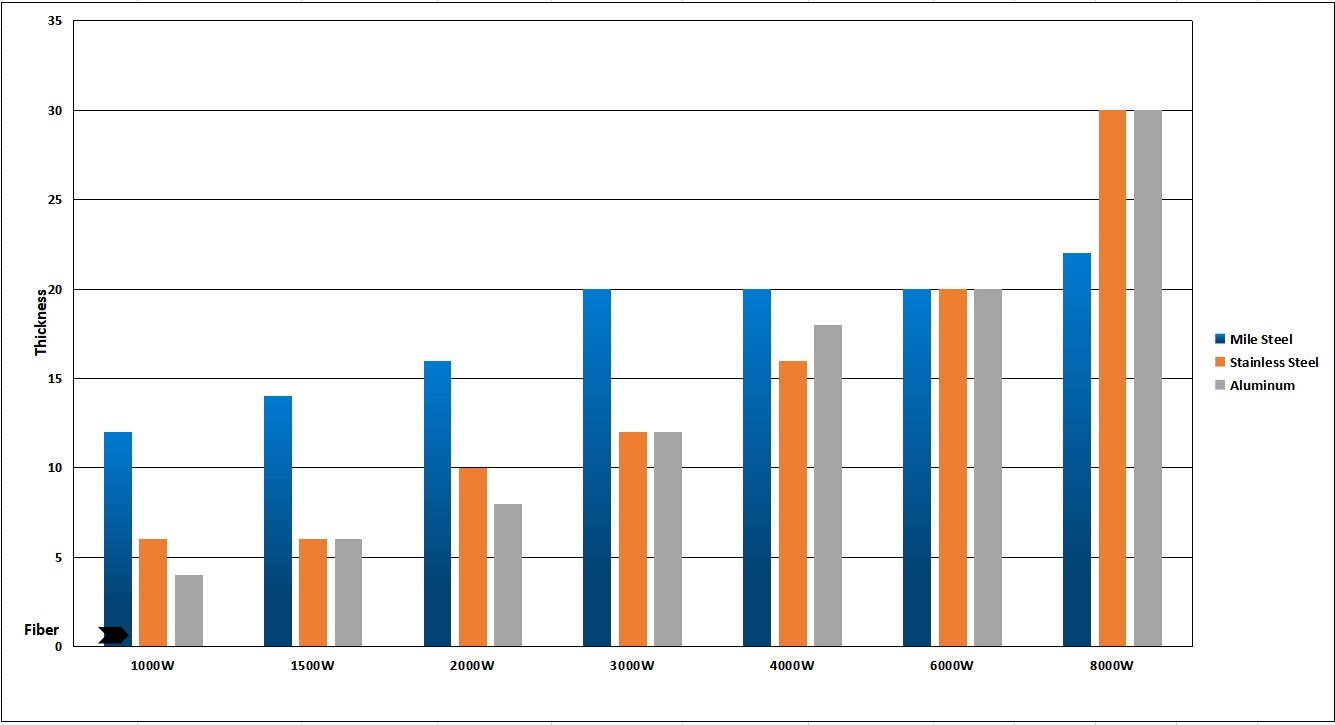

Bokhoni ba ho itšeha

Video ea mochine

Mochini oa ho Laola le ho Laolla Metal Square le Round Tube Fiber Laser Pipe Cutting Machine

Molemo o ka sehloohong oa mochine

1. Ho sebelisa mohloli oa laser oa Raycus, katleho ea phetoho ea electro-optical e phahame, e ka bolokang tšebeliso ea matla nakong ea mosebetsi le ho boloka litšenyehelo tsa ho sebetsa.

2. Bolelele bo tsepamisitsoeng ba hlooho ea ho itšeha bo ka ikemela ka bobona ho latela bophahamo ba holim'a thepa, esita le haeba holim'a thepa e sa bataletseng, boleng ba ho itšeha bo ka tiisetsoa.

3. Ho hlomelloa ka molaoli oa letsoho, u ka laola ka letsoho boemo ba ho itšeha.

4. Ka sekoti se nepahetseng sa bolo, rack le pinion, ts'ebetso ea phetisetso ea tataiso ea linear, kahoo ho finyella ho nepahala ho phahameng, katleho e phahameng le botsitso ba sesebelisoa sa mochine.

5. Phetoho ea valve ea solenoid le valve e lekanang e laoloa ke tsamaiso. Boleng ba ho kenya tsamaisong ea ho laola lipalo bo ka laola boholo ba sephahla sa li-valve tse lekanang, ntle le phetoho ea matsoho

6. Matla a phahameng a matla a kopantsoeng a li-welding fuselage le li-aerospace-grade aluminium alloy libalaka li kenngoa ka mocheso o phahameng oa mocheso ho netefatsa hore nako e telele e sebelisoa ntle le deformation.

Workshop & Packing

1. Moeli oa liphutheloana tse thibelang ho thulana: Likarolo tsohle tsa mochine li koahetsoe ka lisebelisoa tse ling tse bonolo, haholo-holo tšebeliso ea boea ba perela.

2. Lebokose la lehong la Fumigation: Lebokose la rona la lepolanka le fumigated, ha ho hlokahale hore le hlahlobe lehong, le boloke nako ea lipalangoang.

3. Mochine oa ho paka oa filimi eohle: Qoba tšenyo eohle e ka hlahang nakong ea ho pepa. Joale re tla koahela sephutheloana sa polasetiki ka thata ho netefatsa hore thepa e bonolo e koaheloa e tiile, hape e qoba metsi le mafome.

E ka ntle ka ho fetisisa ke lebokose la lepolanka le nang le template e tsitsitseng.

4.Lebokose la lehong le ka tlaase ho sekoti se tiileng sa tšepe bakeng sa ho tšoara habonolo.