Mochini oa Welding oa Laser o tšoaroang ka letsoho

Karolo e khuts'oane ea litaba tsa litaba

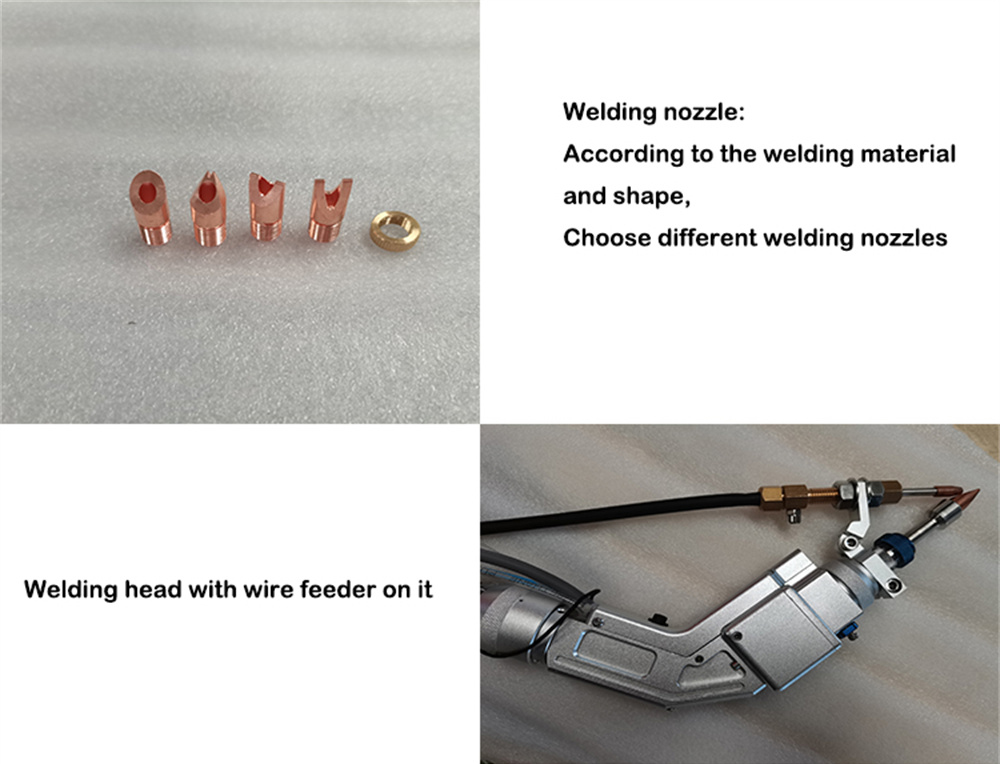

- Ho na le mekhoa e 6 ea ho cheselletsa le li-nozzles tse ngata tsa welding ho fihlela litlhoko tse fapaneng tsa welding; e na le ts'ebetso ea ts'ebetso ea ts'ireletso ea ts'ireletso, e hlahisang laser ka mor'a ho ama tšepe 'me ka boeona e koala leseli ha e tlosoa.

- Mochini o na le sesebelisoa sa othomathiki sa terata, se ka fetolang maemo habonolo le ho fana ka likhetho tse ngata bakeng sa

bareki.

- Ho na le mekhoa e 6 ea ho cheselletsa le li-nozzles tse ngata tsa welding ho fihlela litlhoko tse fapaneng tsa welding; e na le ts'ebetso ea ts'ebetso ea ts'ireletso ea ts'ireletso, e hlahisang laser ka mor'a ho ama tšepe 'me ka boeona e koala leseli ha e tlosoa.

- Mocheso o habeli le taolo e habeli, potoloho ea metsi e potolohang, e ka pholisa kapele phaephe e kahare ea hlooho ea welding, ha e ntse e pholisa laser.

Pontšo ea Sehlahisoa

Tekheniki parameter

| Boemo | E ncha | Likaroloana tsa mantlha | Mohloli oa Laser |

| Tšebeliso | Weld Metal | Max. Matla a Phallo | 2000W |

| Boitsebiso bo sebetsang | Tšepe | Cnc Kapa Che | Ee |

| Mokhoa oa ho Pholisa | Pholiso ea Metsi | Laola Software | Ruida/Qilin |

| Pulse Width | 50-30000Hz | Matla a Laser | 1000w / 1500w / 2000w |

| Boima (Kg) | 300 Kg | Setifikeiti | Ce, Iso9001 |

| Likaroloana tsa mantlha | Fiber Laser Source, Fiber, Tšoara Laser Welding Hlooho | Lintlha tsa bohlokoa tsa ho rekisa | Ho Nepaha Ho Phahameng |

| Mosebetsi | Metal Karolo Laser Welding | Bolelele ba Fiber | ≥10m |

| Liindasteri tse sebetsang | Lihotele, Mabenkele a Liphahlo, Mabenkele a Thepa ea Moaho | Likaroloana tsa mantlha | Phepelo ea Laser |

| Mokhoa oa ho sebetsa | Pulsed | Ka mor'a Tšebeletso ea Warranty | Tšehetso ea Inthaneteng |

| Focal Spot Diameter | 50μm | Wavelength | 1080 ±3nm |

| Tlhahlobo ea Video e Tsoang | Fanetsoe | Sebopeho sa Graphic se tšehelitsoe | Ai, Plt, Dxf, Dwg, Dxp |

| Sebaka sa Tšimoloho | Jinan, Profinseng ea Shandong | Nako ea Tiisetso | Lilemo tse 3 |

Likarolo tse ka Sehloohong bakeng sa Mochini

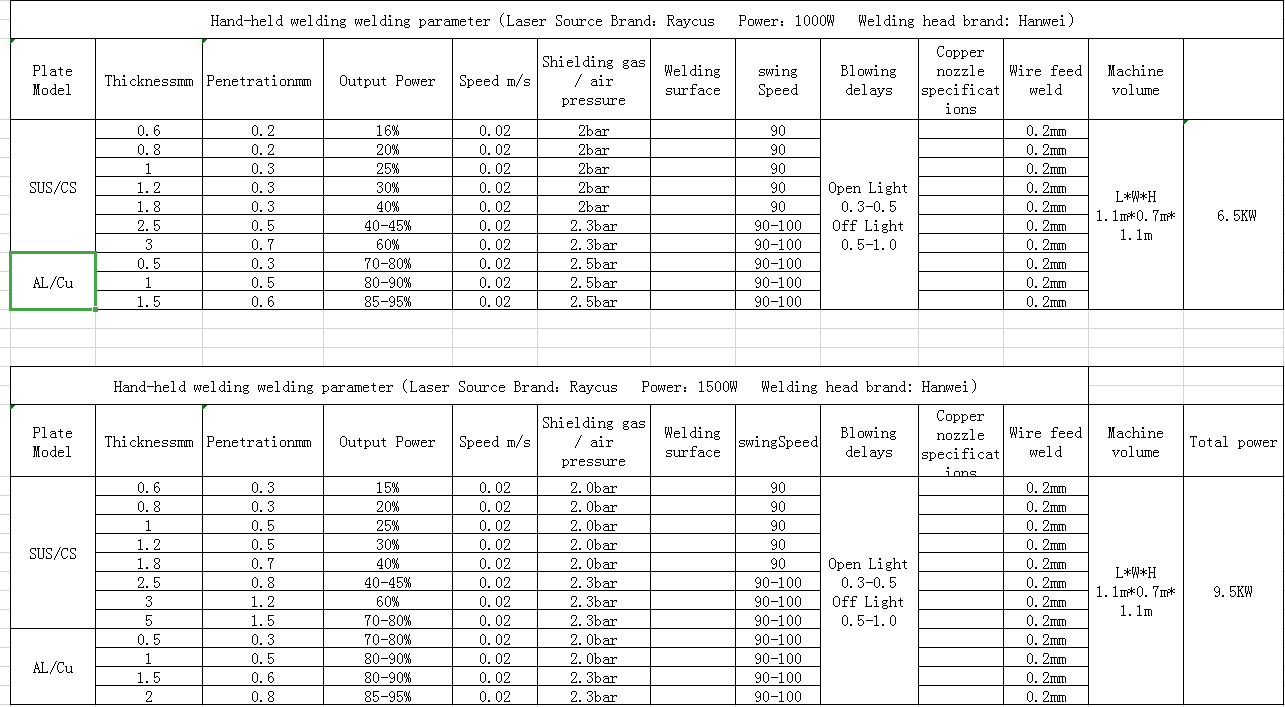

Tekanyetso ea welding bakeng sa mochini oa welding oa laser

Tlhophiso

| Matla a Laser | 1000w | 1500W | 2000W | ||||||

| Lintho tse Welding | Ts'epe e sa beng le mabali | Tšepe ea Carbon | Aluminium | Ts'epe e sa beng le mabali | Tšepe ea Carbon | Aluminium | Ts'epe e sa beng le mabali | Tšepe ea Carbon | Aluminium |

| Botenya ba Welding (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Botenya ba Welding (Inch) |

|

|

|

|

|

|

|

|

|

| Tepo e Fetohang ea Welding | Welding Wire Diameter 0.8-1.6mm | ||||||||

| Tlhokahalo ea Seam Weld | Filler Wire Welding≤1Mm Swinging Welding ≤15% Ea Botenya ba Plates≤0.3Mm | ||||||||

| Boima ba Mochini | 220Kg | 220Kg | 300Kg | ||||||

| Boholo ba Mochini(Mm) | 954X715X1080 | 954X715X1080 | 1155X715X1160 | ||||||

| Welding Gun Line Bolelele | 10m(The Wire Feed Tube Of The Wire Feeder E bolelele ba limithara tse 3) | ||||||||

| Welding Gun Weight | Mofuta oa Seipone sa Vibrating (Qi Lin): 0.9Kg | ||||||||

| Matla a Mochini | 7kw | 9kw | 12kw | ||||||

| Puo e Tsheheditswe | E tloaelehileng: Sechaena, Senyesemane, Sekorea, Sevietnam, Serussia Sejapane le Sepanishe li ka Itloaetsa | ||||||||

| Voltage le Frequency | Maemo: 380V/50Hz Maqhubu a Mang le Maqhubu ke a Boikhethelo | ||||||||

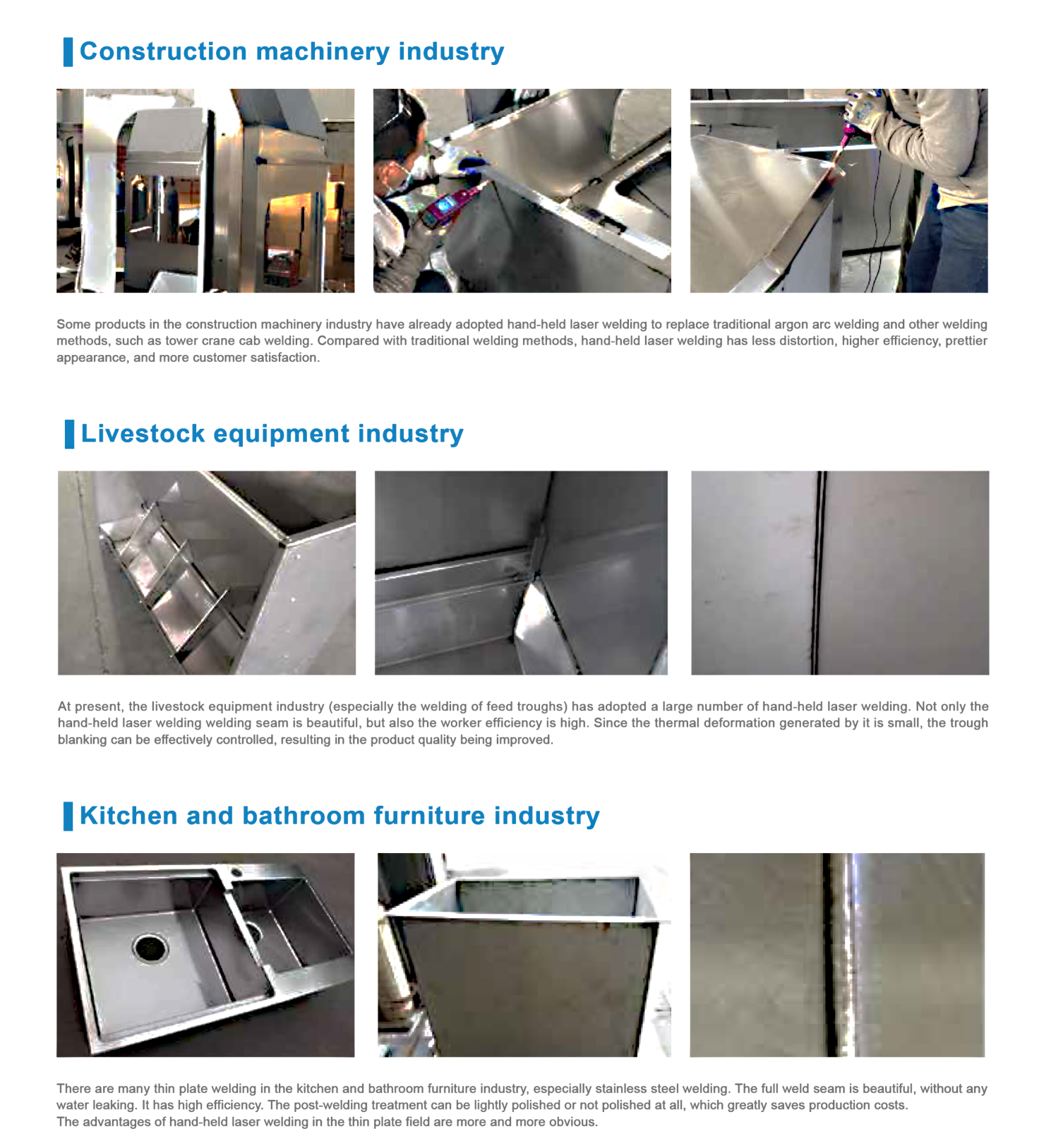

Indasteri ea likopo

Mechini ea tjheseletsa ea Laser e sebelisoa haholo indastering ea ho hlapela: ho tjheseletsa ha manonyeletso a lipeipi tsa metsi, ho fokotsa manonyeletso, li-tee, li-valve le lishaoara. Indasteri ea likhalase: tjheseletsa e nepahetseng ea tšepe e sa hloekang, alloy ea titanium le lisebelisoa tse ling sebakeng sa buckle, foreimi ea kantle le maemo a mang a likhalase. Indasteri ea Hardware: impeller, kettle, handle, joalo-joalo, welding ea likarolo tse rarahaneng tsa litempe le likarolo tsa ho lahla. Mechini ea welding ea laser e sebelisoa haholo indastering ea likoloi: li-gaskets tsa silinda ea enjine, hydraulic tappet seal welding, spark plug welding, welding filthara, jj.

Molemo oa mochine oa welding oa laser

1. Mefuta e mengata ea ho tjheseletsa: Hlooho e ts'oaretsoeng ka letsoho e na le 5m-10m ea pele ea optical fiber, e hlōlang moeli oa sebaka sa workbench 'me e ka sebelisoa bakeng sa ho cheselletsa ka ntle le ho cheselletsa sebaka se selelele;

2. E bonolo ebile e bonolo ho e sebelisa: laser welding e nang le letsoho e na le li-pulleys tse tsamaeang, tse phutholohileng ho li tšoara, 'me li ka lokisoa ka nako leha e le efe, ntle le tlhokahalo ea liteishene tse tsitsitseng, tse sa lefelloeng le tse bonolo,' me li loketse maemo a sa tšoaneng a tikoloho ea ho sebetsa.

3. Mekhoa e fapaneng ea ho tjheseletsa: ho tjheseletsa ka lehlakoreng le leng le le leng ho ka hlokomeloa: ho tjheseletsa ka stitch, ho tjheseletsa butt, welding vertical, flat fillet welding, inner fillet welding, outer fillet welding, joalo-joalo. Welding ka lehlakoreng efe kapa efe ka finyelloang. Ho phaella moo, a ka boela a tlatsa ho itšeha, ho cheselletsa le ho itšeha ho ka fetoloa ka bolokolohi, feela ho fetola nozzle ea koporo ea welding ho nozzle ea koporo ea ho itšeha, e leng bonolo haholo.

4. Phello e ntle ea welding: letsoho la laser welding ke ho chesa fusion e chesang. Ha ho bapisoa le li-welding tsa setso, welding ea laser e na le matla a phahameng a matla mme e ka fihlela phello e ntle ea welding. Mathata a ho sala morao, botebo bo boholo ba tjheseletsa, ho qhibiliha ho lekaneng, ho tiya le ho tshepeha, le matla a weld a fihlang kapa esita le ho feta tshepe ya motheo ka boyona, e ke keng ya netefatswa ke metjhini e tlwaelehileng ya welding.

5. Seam sa ho tjheseletsa ha se hloke ho bentshwa: Ka mora ho tjheseletsa ka setso, ntlha ya welding e hloka ho bentshiwa ho netefatsa boreledi e seng mahwashe. Mochine oa laser o tšoaroang ka letsoho o bontša feela melemo e mengata ea ts'ebetso ea ts'ebetso: ho tjheseletsa ho tsoelang pele, ho boreleli ntle le sekala sa litlhapi, ho ntle ho se na maqeba, le mekhoa e fokolang ea ho sila.

6. Ha ho lisebelisoa tse sebelisoang bakeng sa ho cheselletsa: Ho ea ka maikutlo a batho ba bangata, ts'ebetso ea ho cheselletsa ke "li-goggles ka letsohong le letšehali le terata ea welding letsohong le letona". Leha ho le joalo, ka mochine oa welding oa laser o tšoaroang ka letsoho, ho cheselletsa ho ka phethoa habonolo, 'me litšenyehelo tsa thepa ea tlhahiso le ho sebetsa li fokotsehile.

7. Ka li-alarms tse ngata tsa tšireletso, ntlha ea welding e sebetsa feela ha sesebelisoa se ama ha se ama tšepe, 'me leseli le koalehile ka mor'a hore sesebelisoa sa mosebetsi se tlosoe,' me sesebelisoa sa ho ama se na le mocheso oa mocheso oa 'mele. Tšireletseho e phahameng, ho netefatsa polokeho ea basebetsi nakong ea mosebetsi.

8. Boloka litšenyehelo tsa basebetsi: Ha li bapisoa le li-welding tsa arc, litšenyehelo tsa ho sebetsa li ka fokotsoa ka hoo e ka bang 30%. Ts'ebetso e bonolo ebile e bonolo ho ithuta ebile e potlakile ho ithuta, 'me moeli oa tekheniki oa opareitara ha o phahame. Basebeletsi ba tloaelehileng ba ka hiroa ka mor'a koetliso e khutšoanyane, 'me ba ka fumana liphello tsa boleng ba boleng bo phahameng habonolo.