12m Three-Chuck Automatic Feeding Tube Laser Cutting Machine

Pontšo ea Sehlahisoa

Tekheniki parameter

| Kopo | LaserTube ea ho khaola | Boitsebiso bo sebetsang | Metal Lisebelisoa |

| Letšoao la Mohloli oa Laser | Raycus / MAX | Palo ea li-chucks | Li-chucks tse tharo |

| Boholo ba bolelele ba liphaephe | 12 M | Ho nepahala ha maemo a phetoang | ≤±0.02 limilimithara |

| Sebopeho sa phala | E pota-potile, tube ea lisekoere, liphaephe tse khutlonnetsepa,lipeipi tse nang le sebopeho se khethehileng,tse ding | Mohloli oa Motlakase (Tlhoko ea Matla) | 380V/50Hz/60Hz |

| Sebopeho sa Graphic se tšehelitsoe | AI, PLT, DXF, BMP, Dst, Dwg, DXP,ETC | CNC kapa che | Ee |

| Setifikeiti | CE, ISO9001 | Ctsamaiso ea lijo | Metsi phodiso |

| Mokhoa oa Ts'ebetso | Tsoelang pele | Sebopeho | Tlhokomelo e tlase |

| Tlaleho ea Teko ea Mechini | Fanetsoe | Video e tsoa tlhahlobo | Fanetsoe |

| Sebaka sa Tšimoloho | Jinan, Profinseng ea Shandong | Nako ea tiisetso | 3 lilemo |

Video ea mochini

Litšobotsi tsa Mochini oa 1210 o Moholo oa ho Splicing Laser Marking :

1. Moralo oa li-chuck tse tharo (li-chuck tse tharo tsa pneumatic)

1) Li-chucks tse ka pele, tse bohareng le tse ka morao: rarolla bothata ba ho sisinyeha ha lipeipi le ho senyeha ha lipeipi tse telele

2) Tšehetsa ho itšeha ho khuts'oanyane ha lisebelisoa tsa mohatla, ka katleho ho fokotsa litšila tsa thepa

3) Chuck e bohareng e ea sisinyeha, ka katleho e ntlafatsa tšehetso le ho nepahala ha ts'ebetso

2. Sistimi ea ho fepa ka boiketsetso ea limithara tse 12

1) E amohela mochini oa ho fepa liphaephe ka botlalo + sistimi ea taolo ea servo

2) E hlokomela phepelo e tsoelang pele ea liphaephe tse ngata le ho itšeha ka botlalo

3) E boloka mosebetsi, e ntlafatsa ts'ebetso, 'me e loketse ts'ebetso ea li-oda tse ngata

3. Mokhoa oa ts'ehetso o bohlale oa ho latela

1) Tšehetso ea ho latela nakong ea ts'ebetso ea liphaephe ho boloka phala e tsitsitse le ho thibela ho sisinyeha

2) Ntlafatsa ho nepahala ho itšeha le ho sireletsa hlooho ea chuck le laser

4. E ka khaola mefuta e fapaneng ea liphaephe tse nang le sebōpeho se khethehileng

1) Ts'ehetso ea ho itšeha: liphaephe tse chitja, liphaephe tse lisekoere, liphaephe tse nang le mahlakore a mabeli, liphaephe tsa elliptical, lipeipi tse nang le hexagonal, litšepe tsa channel, litšepe tsa angle, joalo-joalo.

2) Mosebetsi oa boikhethelo oa ho itšeha ho fihlela litlhoko tse rarahaneng tsa welding pretreatment

5. Laser ea fiber e matla e phahameng

1) Li-lasers tsa mofuta oa MAX/RAYCUS/IPG ka boikhethelo

2) Lebelo la ho itšeha ka potlako, karolo e boreleli ea sefapano, ha ho na li-burrs

3) Theko e tlaase ea tlhokomelo, ts'ebetso e tsitsitseng

6. Mokhoa o khethehileng oa ho itšeha oa CNC

1) Mananeo a bohlale a litšoantšo (a lumellana le Lantek, Tubest, Artube, joalo-joalo)

2) Ts'ehetsa ho fumanoa ha moeli oa othomathike, matšeliso, papiso ea ho itšeha

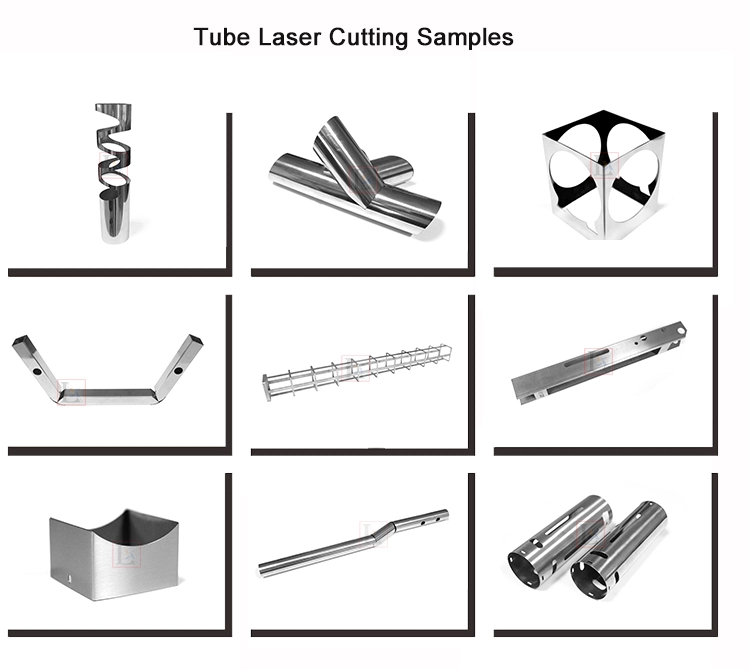

Ho khaola lisampole :

Tshebeletso

1. Tlhophiso ea lisebelisoa: bolelele ba ho itšeha, matla, boholo ba chuck, joalo-joalo bo ka etsoa ho latela litlhoko tsa bareki.

2. Ho kenya le ho lokisa liphoso: fana ka tataiso ea sebakeng sa marang-rang kapa e hōle ho netefatsa ts'ebetso e tloaelehileng ea lisebelisoa.

3. Koetliso ea tekheniki: koetliso ea ts'ebetso, tšebeliso ea software, tlhokomelo, joalo-joalo, ho netefatsa hore bareki ba na le tsebo ea ho sebelisa thepa.

4. Tšehetso ea botekgeniki e hole: araba lipotso inthaneteng le ho thusa u le hole ho rarolla mathata a software kapa ts'ebetso.

5. Likarolo tsa lisebelisoa: phepelo ea nako e telele ea lisebelisoa tsa bohlokoa tse kang fiber lasers, lihlooho tsa ho itšeha, li-chucks, joalo-joalo.

Litherisano tsa 6.Pre-sales le tšehetso ea tekheniki:

Re na le sehlopha se nang le boiphihlelo sa baenjiniere ba ka fang bareki boeletsi ba litsebi tsa pele ho thekiso le tšehetso ea tekheniki. Ebang ke khetho ea lisebelisoa, keletso ea kopo kapa tataiso ea tekheniki, re ka fana ka thuso e potlakileng le e sebetsang hantle.

7.Quick karabo ka mor'a thekiso

Fana ka tšehetso ea tekheniki ka mor'a thekiso e potlakileng ho rarolla mathata a fapaneng ao bareki ba kopanang le ona nakong ea ts'ebeliso.

LBH

P: Mochini oo oa ho itšeha oa laser tube o ka khaola bokae?

A: E ts'ehetsa bolelele bo boholo ba limithara tse 12, bophara ba bophara ba Φ20mm–Φ350mm bakeng sa li-tubes tse chitja, 'me e tšehetsa mahlakore a fapaneng a ≤250mm bakeng sa li-square tubes (litlhaloso tse khōloanyane le tsona li ka etsoa).

P: Melemo ea moralo oa li-chuck tse tharo ke efe?

A: Li-chuck tse tharo li khona ho koala le ho tšehetsa li-tubes tse telele, ho thibela ho sisinyeha, le ho ntlafatsa ho itšeha ho nepahetseng. Chuck e bohareng e ea sisinyeha, e ts'ehetsa ho itšeha ha mohatla le lisebelisoa tsa ho boloka.

P: Ke mefuta efe ea li-tubes e ka khaoloang?

A: E tšehetsa li-tubes tse chitja, li-square tubes, li-tubes tse nang le mahlakore a mabeli, li-oval tubes, li-tubes tse pota-potileng letheka, li-channel, li-angle irons, li-tubes tse nang le sebōpeho se khethehileng, joalo-joalo.

P: Na ho fepa le ho palamisa ho iketselitse ka botlalo?

A: E, e na le mokhoa oa ho jarolla ka ho iketsa, o ka khonang ho tšoara li-tubes tse ngata ka nako, ho itlhophisa, ho lemoha, le ho laela, ho ntlafatsa katleho le ho boloka mosebetsi.

P: Mesebetsi ea ts'ireletso ea polokeho ke efe?

A: Thepa e na le sekoaelo sa laser tšireletso, konopo ea ho emisa ts'ohanyetso, senotlolo sa polokeho, sistimi ea alamo ea motlakase ho netefatsa ts'ebetso e bolokehileng le ho fihlela litekanyetso tsa CE (tse loketseng ho romelloa kantle ho naha).

P: Joang ho hlophisa ho kenya, ho laela le ho koetlisa?

A: Re fana ka "ts'ebeletso ea ho kenya le ho laela sebakeng sa marang-rang" 'me re fana ka koetliso ea tsamaiso bakeng sa basebetsi (inthaneteng + offline boikhethelo). Bareki ba mose ho maoatle ba tšehetsa tataiso ea video le buka ea ts'ebetso ea Senyesemane.

P: Na e ka etsoa ka mokhoa o ikhethileng?

A: Ho joalo! Re ka Customize boholo ba rack, ho itšeha bokgoni, chuck foromo, jarolla ka ho iketsa tsamaiso ea, joalo-joalo ho ea ka litlhoko tsa bareki ho kopana le litlhoko tse khethehileng tsa ho sebetsana le liindasteri tse fapaneng.